APEN0H-028CH33A0308

3

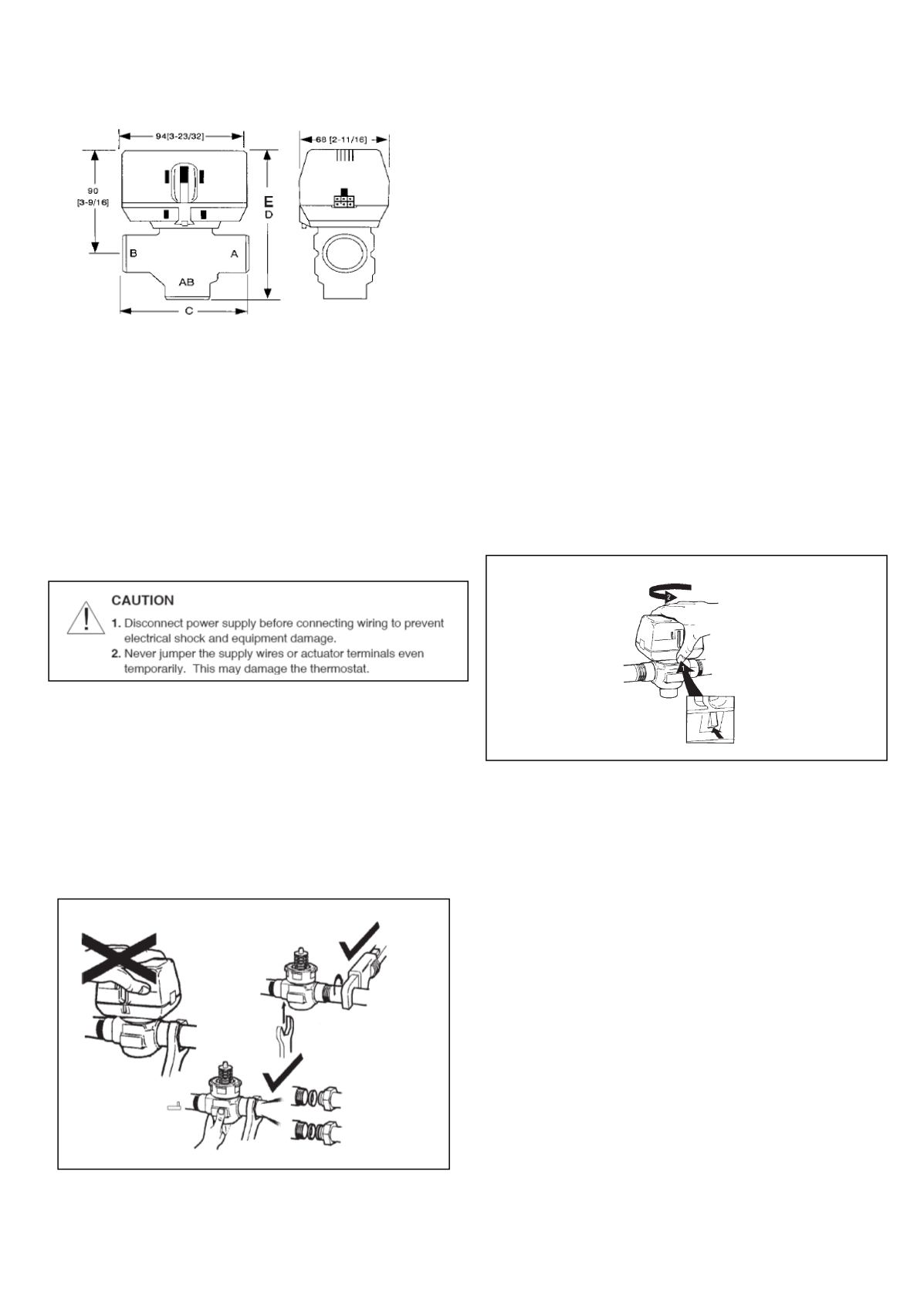

Fig.4– 3-way nominal dimensions in inches andmillimetres

INSTALLATION

WHEN INSTALLINGTHISPRODUCT:

1

.

Read these instructions carefully. Failure to follow them could

damage the product or cause ahazardous condition.

2. Check the ratings given in the instructions and on the product to

make sure the product is suitable for your application.

3. Installermust be a trained, experienced service-person.

4. Always conduct a thorough check-out when installation is

completed.

5. Whilenot necessary to remove the actuator from thebody, it can

be removed for easeof installation. The actuator canbe installed

in any of the four orientations to suit themost convenient wiring

direction. Actuator latchingmechanismworks onlywhen the lengths

of theactuator and the valve bodyare parallel toeach other.

6. Anextra 25mm head clearance is required to remove the actuator.

PLUMBING

The valvemay be plumbed inanyangle but preferably not with theactuator

belowhorizontal level of thebody.Make sure there is enough room around

the actuator for servicing or replacement.

For use in divertingapplications, the valve is installedwith the flowwater

entering through bottom port AB, and diverting through end portsAor B.

Inmixing applications the valve is installedwith inlet toAor Band outlet

throughAB.

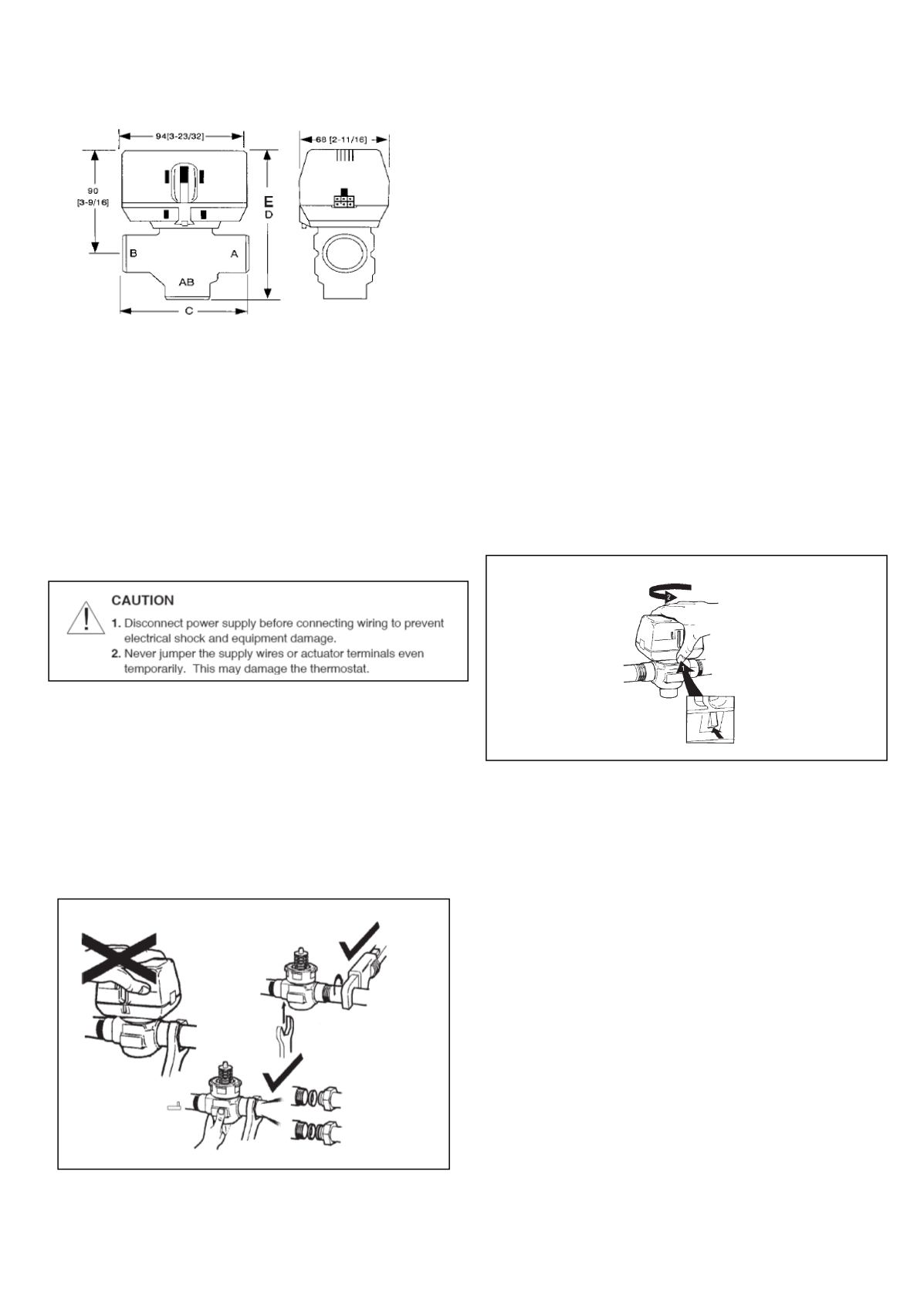

Mount the valve directly in the tube or pipe. Donot grip theactuator

whilemaking and tighteningup plumbing connections. Either hold valve

body in your hand or attach adjustable spanner (38mm or 1-1/2") across

hexagonal or flat faces on the valve body. (Figure 5)

TO INSTALLREPLACEMENTACTUATOR

IMPORTANT

Installationof anew actuator does not requiredraining the

system, provided the valvebody and valve cartridge

assembly remain in thepipeline.

1. Check replacement part number and voltage ratings formatch

witholddevice.

2. Disconnect power supply before servicing toavoidelectrical shock

or equipment damage.

3. Disconnect leadwires toactuator.Whereappropriate, label wires for

rewiring.

4. The actuator head is automatically latched to the valve. To remove,

press up on the latch mechanism with your thumb. It is located

directly below the white manual open lever (see figure 6 below).

Simultaneously press the actuator down towards the body with

moderate hand force and turn the actuator counter-clockwise by 1/8

turn (45degrees). Lift theactuator off the valvebody.

NOTE

: The actuator can also be installed at right angles to the

valve body but in this position the latchmechanismwill not

engage

.

5. Install thenew actuator by reversing theprocess in (4).

6. Reconnect leadwires.

7. Restorepower, and check-out operation.

MANUALOPENERE

Themanual opener can bemanipulated onlywhen in the up position.

The "A" port canbemanually openedby firmly pushing thewhite

manual lever down tomidway and in. In this positionboth the "A"

and "B" ports areopen, andwith auxiliary switchmodels the switch

is closed. This "manual open" positionmay beused for filling,

venting anddraining the system, or for opening the valve in caseof

power failure. The valve canbe restoredmanually to the closed

positionby depressing thewhitemanual lever lightly and then pulling

the lever out. The valveandactuator will return to theautomatic

positionwhenpower is restored.

NOTE

:

If the valve is powered open, it cannot bemanually closed,

unless actuator is removed.

WIRING

See figure

7

for singleunit wiringdetails.

Multiple valvesmay be connected inparallel toa single controller

and transformer, up to the current ratingof the controller and

transformer

.

Fig. 5 - Plumbing theVCValve

Fig.6-LatchMechanism to detachActuator