V5013PTHREE-WAYTHREADEDGLOBEVALVE

APEN0H-004TW01A0604

6

V5013PTHREE-WAYGLOBEVALVES

INSTALLATION

When Installing thisProduct.

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2.

Check the ratings given in the instructions and on

the product tomake sure the product is suitable for

your application.

3.

Installermust be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

1. Do not lift the valve by holding the stem.

2. Do not mount the valvewith the stempointed lower than

horizontal.

3. Mount the valvewith the flow arrow pointed in the direction of

flow through the valve.

4. Mount the valve between aligned pipes. Mounting the valve

on pipes that are not aligned causes leakage at the valve to

pipe connection.

5. Ensure complete engagement on pipe to valve body threads.

6. Hold the valve bodywith a clamp or pipewrench on the

hexagonal fitting nearest the pipe to prevent damage to the

valve bodywhilemounting on the pipe. Refer toFig. 7.

7. Be sure to allow enough room for installation and service.

Clearance for valve installation is dependent on the actuator

size and valve pipe size.

Location

Select a locationwhere the valve, linkage (if used), and

actuator to be used arewithin the appropriate ambient

pressure and temperature ratings.

Leave sufficient clearance above the valve to

accommodate actuator installation and room for servicing

the valve body. (Completely install the valve body in the

pipe line before installing the actuator and linkage.)

When selecting a location for the valve, consider actuator

mounting restrictions. Modutrol IV

TM

Motors require

crankshafts to bemounted horizontally.

Mounting

The preferredmounting position of the valve iswith the

stem vertical. Do not mount the valvewith the stemmore

than 90 degrees from the vertical (pointing lower than

horizontal). Scale and foreignmaterial can collect and can

score the stem and cause packing leakage. Protect the

stem from damage due to bending or scratching.

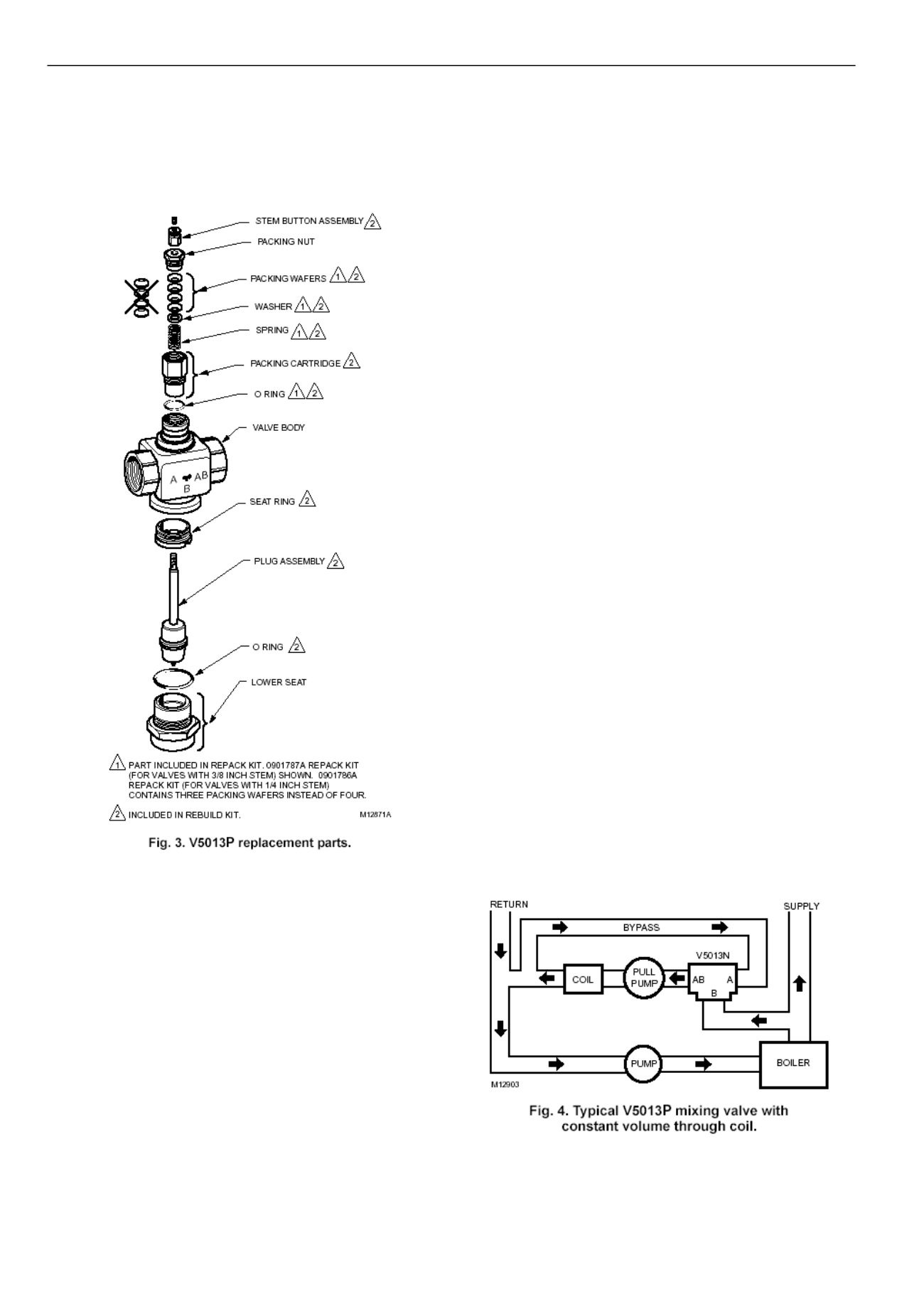

PipingHookups

All pipingmust complywith local codes and ordinances.

Refer toFig. 4 through 6 for typical piping hookups.