13

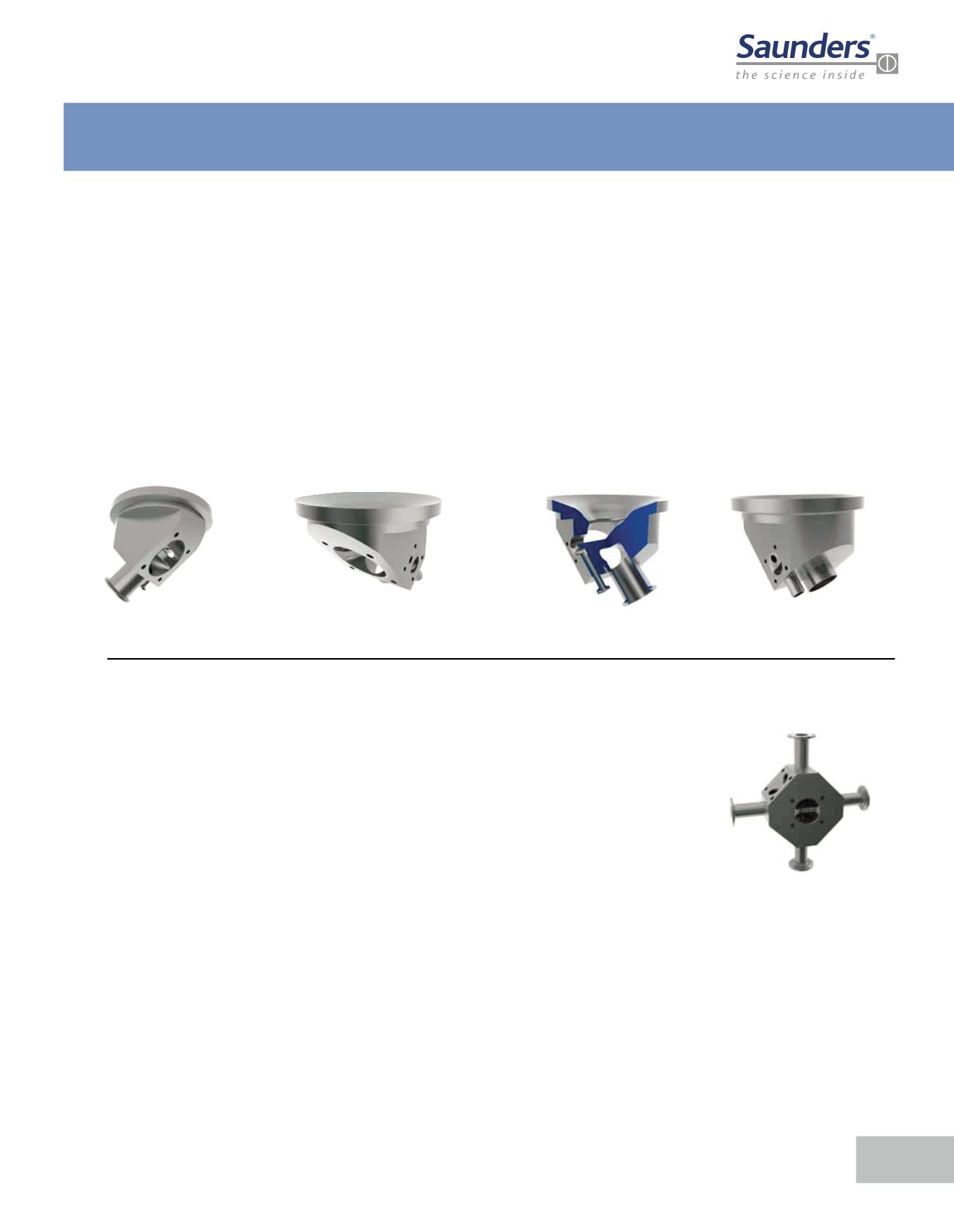

TankBottomValves

The CRANE ChemPharma, Saunders tank bottom valve

incorporates the performance and features of a diaphragm

valve intoamachined from solid tankoutletdesign.

These valves are free from fabricationwelds and deadlegs,

enhancing structural integrity and reducing the potential

for process contamination. The absence of deadlegs also

improvesdrainability, and facilitateseffectivemixing.

Tankbottomvalveweld installationat lowpoint of vessel base

enablingoptimumdrainage, cleaningand sterilization

Internal purgeoptionsavailableeither onvessel side

or outlet sidedependingon system requirements

Almost every process system includes a unique piping

challenge that does not lend itself to conventional solutions.

CRANE ChemPharma, Saunders custom designed Bio-Block

valves replace welded clusters, manifolds, and valve/fitting

combinationsandoffer themost compact,minimumdeadleg

design foroptimumprocess integrity.

Bio-BlockControlled InletOptions

(MultipleWeirandSerialWeir)

Generally associated with multi-port designs, this option

involves machining a weir at the inlet to the common

chamber of a Bio-Block valve. This design permits control of

flow entering into the multi-port valve. The controlled inlet

optioncanbe included inanynumberofcompoundBio-Block

solutions tocomplywith specific system requirements.

AsepticDiaphragmValves

TankValveOptions

Samplevalves, purgevalves andports areeasily incorporated

into the tank bottom design to achieve the desired

performance.

The resulting valve types are a hybrid or compound solution

that entails the use of more than one valve concept; for

example, combininga tankbottomvalvewithanaccess

valve,amulti-portvalvewithaccessvalvestoperformassteam

and condensate port or a point-of-use valve together with a

samplevalve. Thisprocess, combinedwithourmanufacturing

expertise, results incustomvalveconfigurations that combine

utilityandperformance.

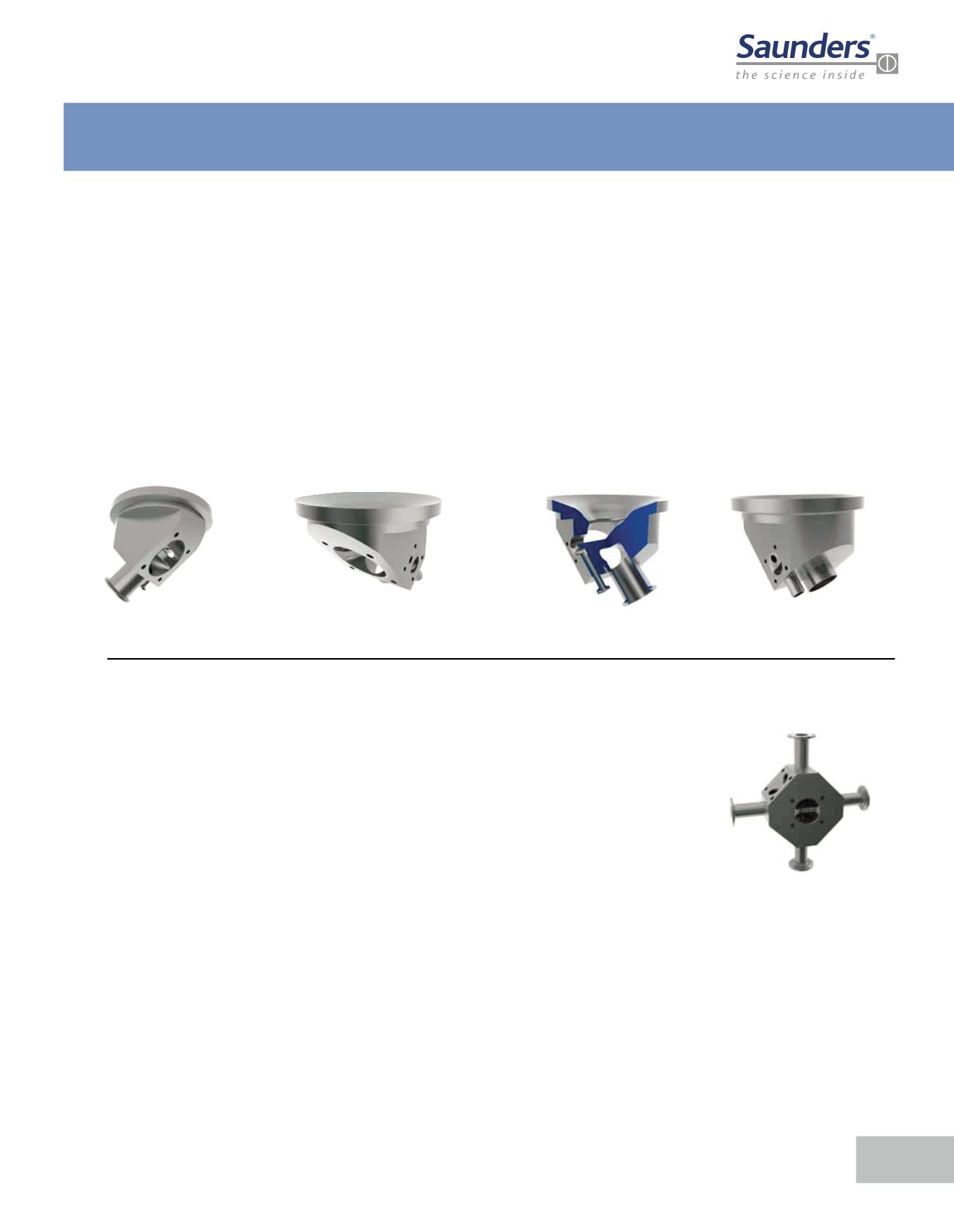

Bio-BlockChromatographyValves

(MultipleWeirandStandard2Way)

This

Bio-Block

option

incorporates a central control

weirtopermitthedivisionofflow

into distinct process streams or

toallow flow topass through the

valve as required during resin

regenerationor cleaningcycles.

Bio-BlockCompondSolutions

Bio-BlockCustomizedSolutions

Our design teamswork closelywith customers to createunique

machined valvedesigns called call Bio-Blocks. These ‘outsideof

the box’ solutionsmay be drivenby process, space constraints,

regulatory issuesorother specific requirements.

Machined Bio-Blocks have the advantages of reduced wetted

area and deadlegs, no internal fabrication welds and reduced

documentation for installation and validation. Faster and

easier installation of process manifolds can be achieved using

advanced “machined from solid” valves.