8

TandemValves (SterileAccessValves)

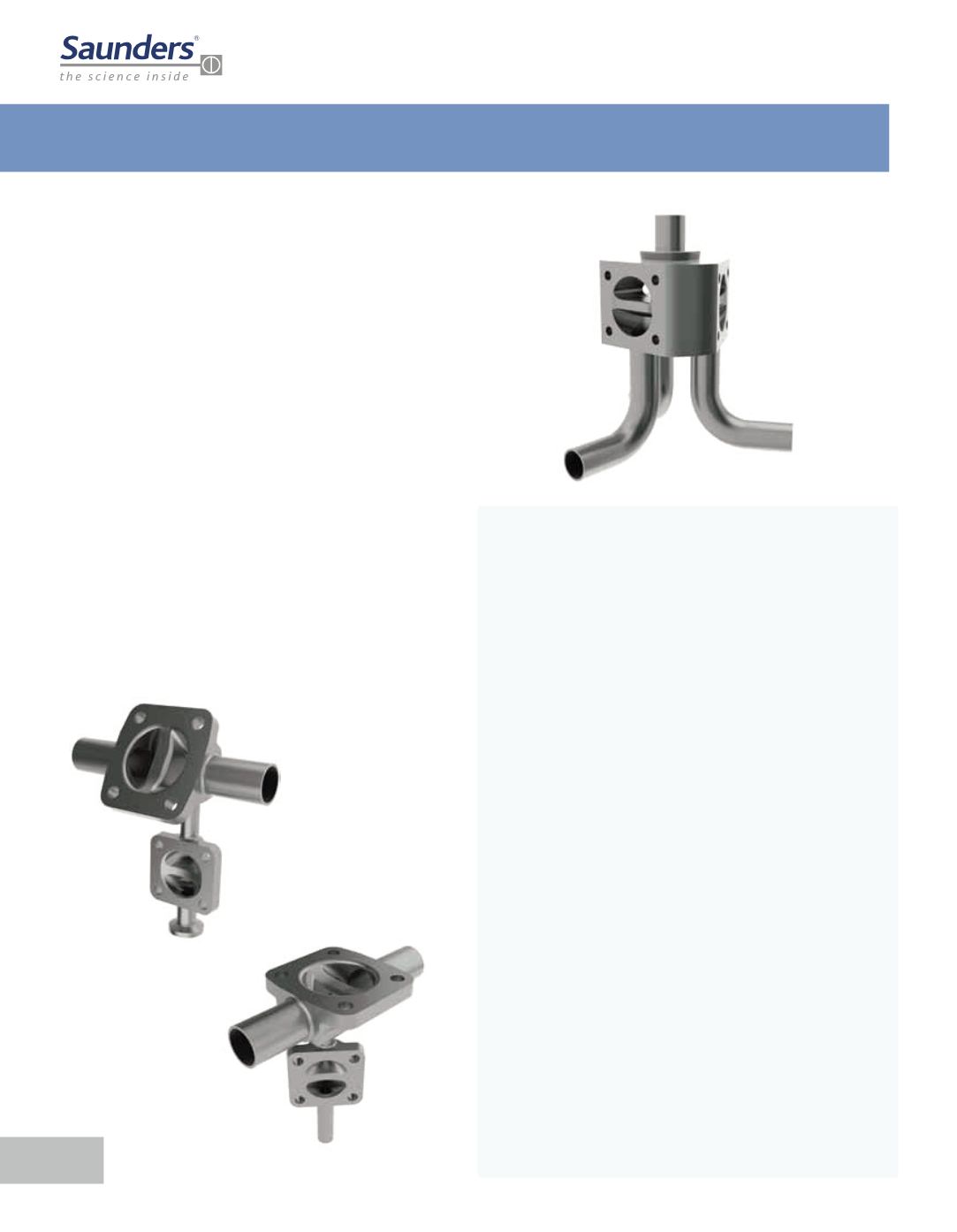

The first customized valve concept is the welded tandem

combination. A main valve is ported and a second access

valve iswelded to themain valve to create a tandem cluster.

Tandem valves are designed to optimize drainability and

meetprocessdesign requirements forminimumdeadlegs.

CustomValveSolutions

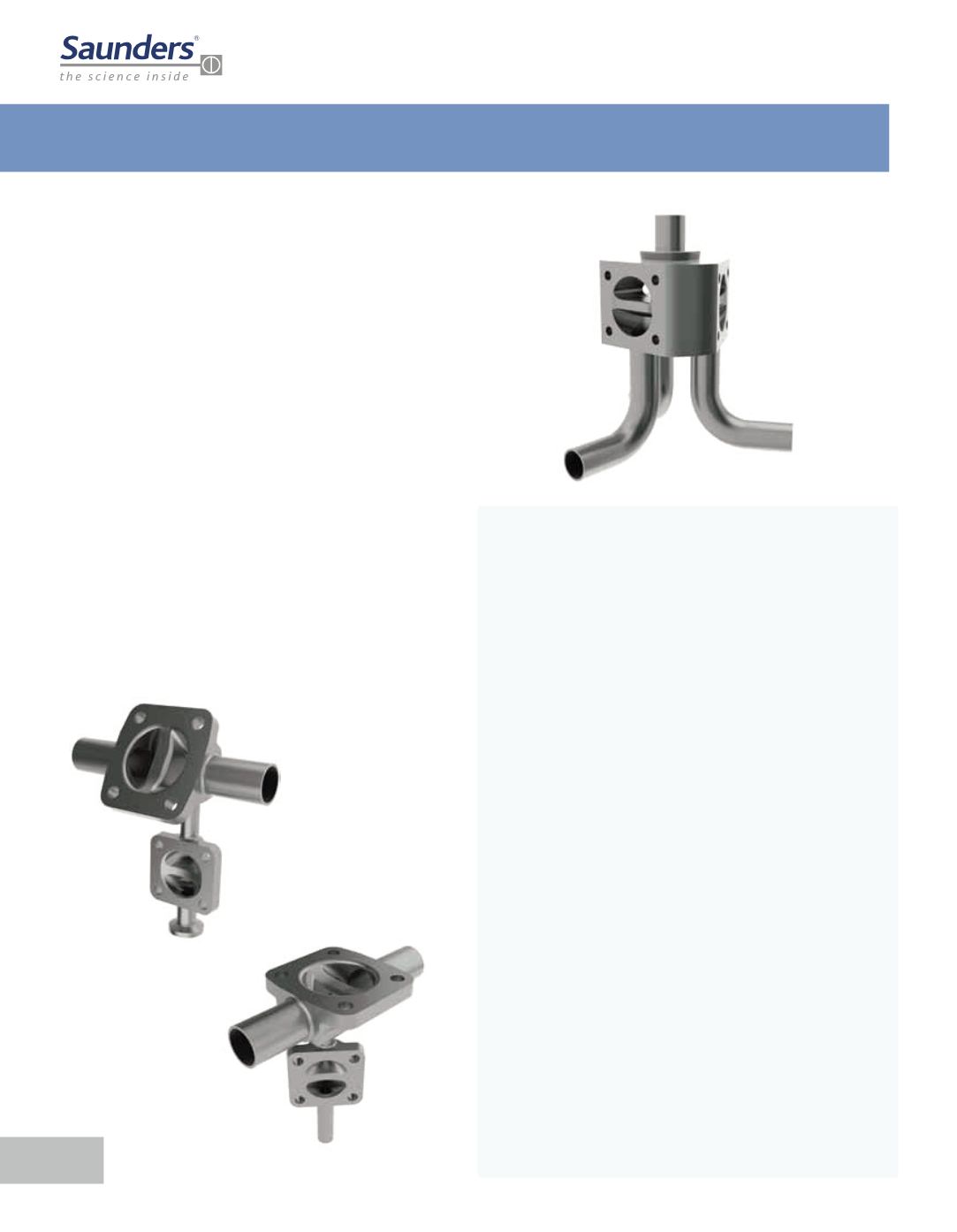

Customvalve typesmaybewelded tandemvalveassemblies,

machined fromsolidblock typesormanifolds that incorporate

both technologies.

The primary benefits of these solutions are reduced wetted

area, reduced deadlegs, improved drainability and reduced

design envelope over arrangements using individual 2-way

valvebodies.Machined from solidbodies alsooffer increased

securitydue to the lackof internal fabricationwelds.

The following ruleshelpdefine thepossibleorientationof

tandemvalves:

· Themainvalveandaccess valvemaybe installed to

drain ineither thehorizontal or vertical position.When

installed inahorizontal run thevalvemust be rotated

into the self-drainposition todrain.

· Allowancemust bemade topermit access tobonnet or

actuator fasteners and for diaphragmmaintenance.

· Theaccess valve canbeany size including the same size

as themainvalve.

· Theamount of deadlegbetweenmainandaccess

valveswill varydependingon respectivevalve sizes and

orientation.Virtuallyall combinations fallwithin cGMP

requirements.

· “Handwheel opposite”designsgenerallyhave reduced

deadlegs in comparison to configurationswith the

handwheel of themainandaccess valves in the same

quadrant.

· All CRANEChemPharma,Saundersweldedvalve

fabrications are100%hydro-testedbeforeandafter all

weldingandpolishingprocesses toensuremechanical

integrity.

· Fullmaterial certificationof all tubeand fittingsused is

standard.

· CRANEChemPharma,Saundersbonnets,actuators,and

diaphragms fit fabricatedvalveassemblieswithout

adaptorsor distancepieces.

AsepticDiaphragmValves

CustomValveSolutions