4

AsepticDiaphragmValves

BodyRanges

SaundersBodyRange

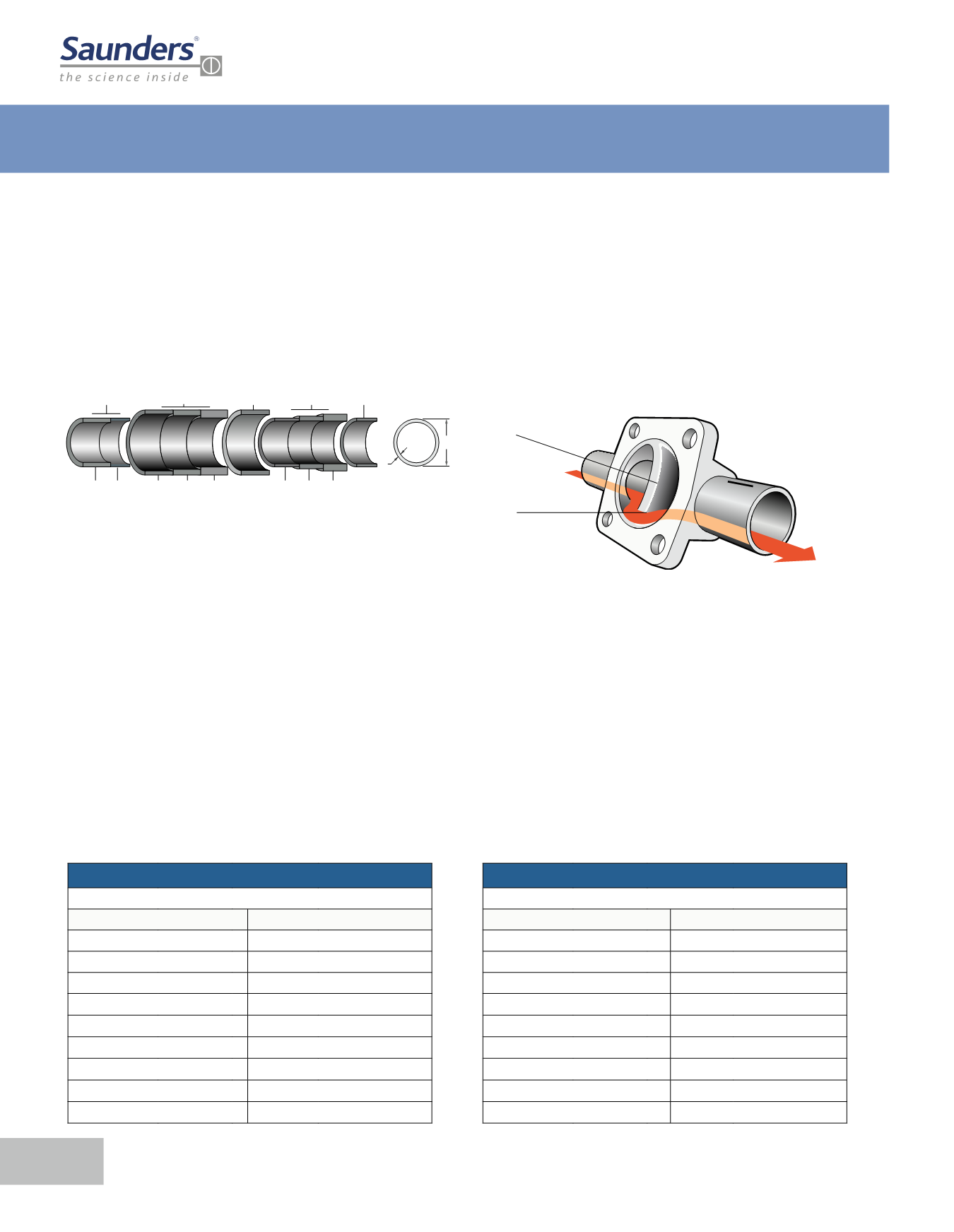

CRANE ChemPharma, Saunders offers valves with bore and

end specifications compliant to the full range of global

pipe standards. The dimensions of outside diameter and

wall thickness differ according to the tube specification as

illustrated in theexample shownbelow fornominal sizeDN25

(1.00”).

Different tube standards have different bore diameters. This

results in changes to the internal geometryof the valvebody

andcausesdrainangles tovarybasedonboth tube standards

andalsonominalvalvesize.AllCRANEChemPharma,Saunders

bodiesaremodeledusing3Dsoftwarethat identifiesoptimum

drainangle for eachvalve sizeand tube specification.

Standardbodymaterial for all forgedbodies is stainless steel

dual certified to 316L(ASTM A-182) &DIN1.4435 with the

additional specification for controlled sulfur, 0.0017%-0.05%.

This provides conformity with most major international

specification requirements and compatibility with bio-

pharm piping systems. Controlled sulfur provides enhanced

weldability and meets the requirements of the ASME BPE

Standard.

S

16swg 18swg

5S

10S

40S

Series1 Series2 Series3

BSO.D.-Rohr

Schedule

ISO1127

DIN11850

SMS3008

ØD

Cast bodies are available from 316L stainless steel. Bodies

produced fromalternatematerials suchasHastelloy®, AL6XN,

904LandTitaniumarealsoavailable.

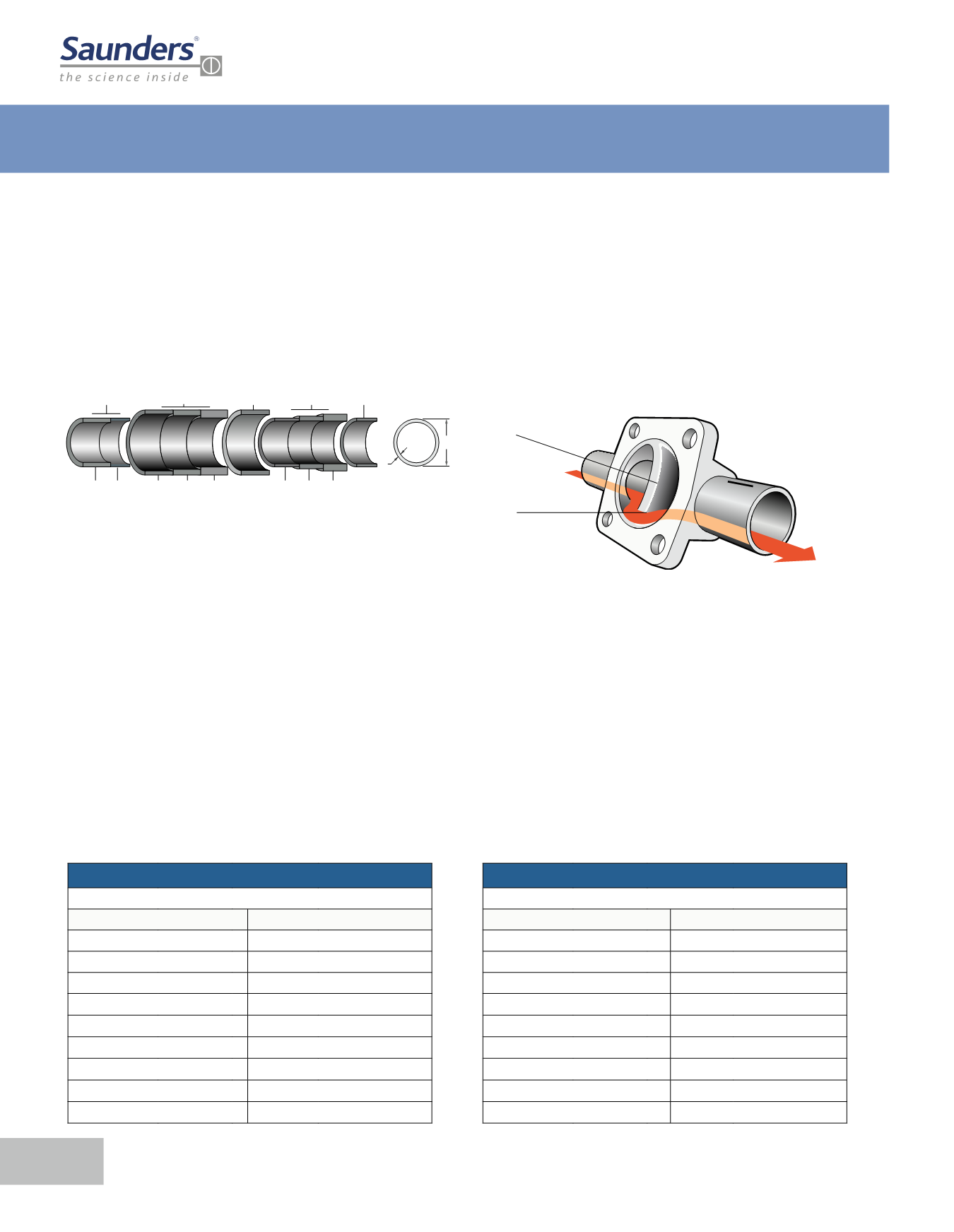

Factorswhichaffect drainability include:

·Valve sizeandend specification

· Internal surface finish

·Drainorientation (as shown)

· Surface tensionandviscosityofmedia

· Pipe runangle–generally recommendedat 2 to3

degrees

Drainability

The diaphragm valve has outstanding self-draining

characteristics and is capable of draining inboth vertical and

horizontal orientations.

Drainability inaprocess system isultimately the responsibility

of the systemdesigner and enduser as a result of the factors

denotedabove.

a

Material

ASMEBPETableDT-3

Element

%

Carbon

0.03max.

Silicon

1.00max.

Manganese

2.00max.

Nickel

12.50min.

Chromium

17.00min.

Molypdenum

2.50min.-3.0max

Nitrogen

.0110max.

Phosphorus

0.040max.

Sulfur

12.50min.-0017max.

Material

DIN1.4435/316LEN10222-5ASTMA-182

Element

%

Carbon

0.03max.

Silicon

1.00max.

Manganese

2.00max.

Phosphorus

Sulphur

0.03max

Chromium

17.0/19.0

Nickel

12.5/15.0

Molybdenum

Nitrogen

0.11