23

T: 936-588-8350 • F: 936-588-8381 • www.craneenergy.com

Duo-ChekValves

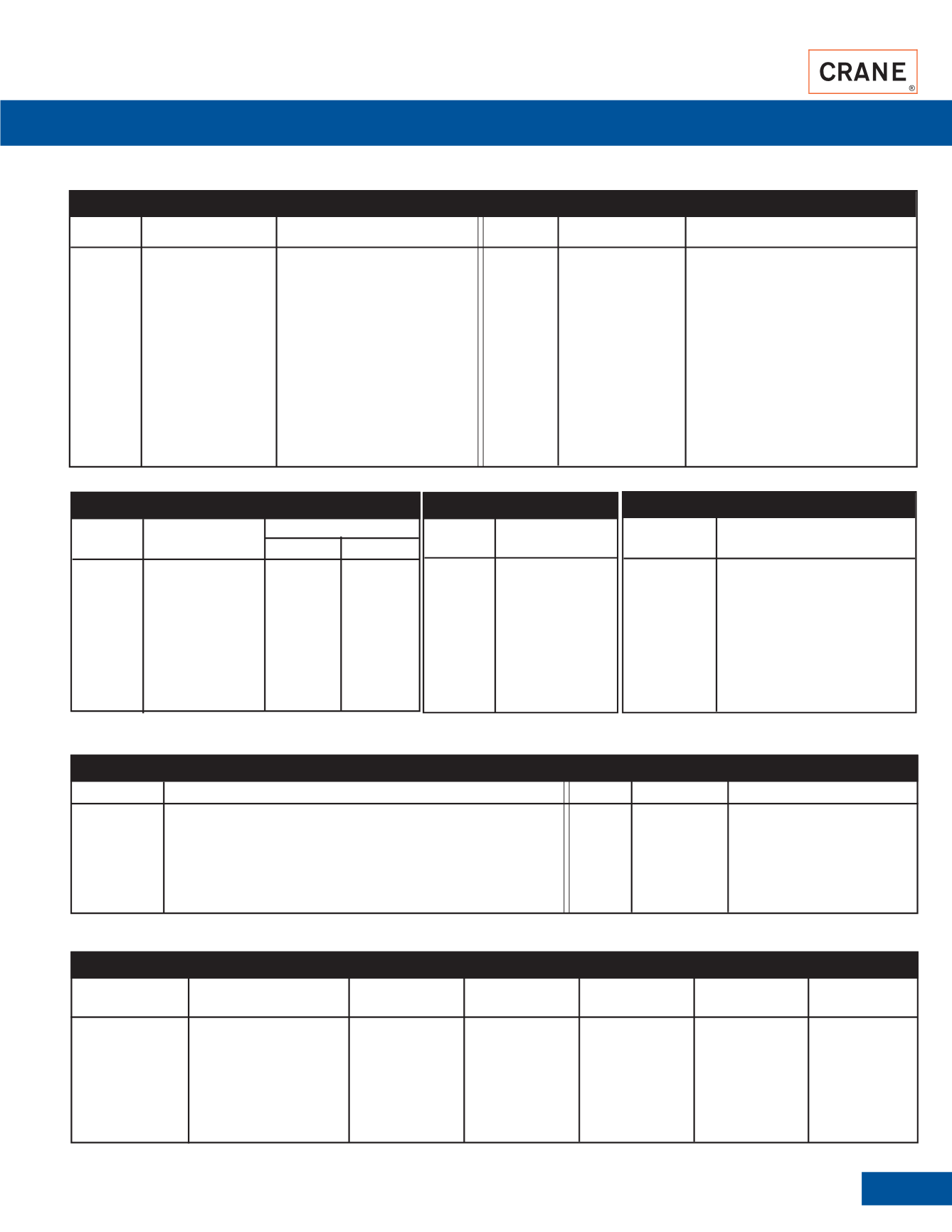

Mod.No.

Material Description

-9

Inconel X-750Springs

-14

316S.S.Plate, Pins

-39

410S.S.Plate, Pins& Inconel X-750Springs

-201

316S.S.Plate, Pins, Inconel X-750Springs

-233

316S.S.Plate, Pins, Inconel X-750Springs and 316S.S.OverlaySeat

-169

410S.S.Plate, Pins, Inconel X-750Springs and 410S.S.OverlaySeat

-772

Monel Plate, Pins, Springs, Bearings andMonel OverlaySeat

Ordering Information

Body andPlates

Seal*

Ordering

Material

OperatingTemperature

Letter

°C °F

A EPDM

-54 to 149 -65 to 300

B3

EPDM (NSF-61)

-54 to 149 -65 to 300

M Buna-N

-57 to 121 -70 to 250

N Neoprene

-40 to 121 -40 to 250

P AsBody

-29 to 538 -20 to1000

S Silicone

-101 to 260 -150 to 500

U RefrigerationGrade -40 to 121 -40 to 250

V Viton-B

®

-29 to 204 -20 to 400

* This range of operating temperatures is for general guidance.The range varieswith application,body andplatematerial.

®

Viton is a registered name of DuPont.

EndConnections

Ordering

Connections

Letter

F

Serrated face

G Grayloc

®

Hub

P PlainFace

(non serrated)

R Ring Joint

W Weld-End

Special BodyConfigurations

CommonModifications

Note:

Numerous additional modificationsmay be specified. Please consult factory.

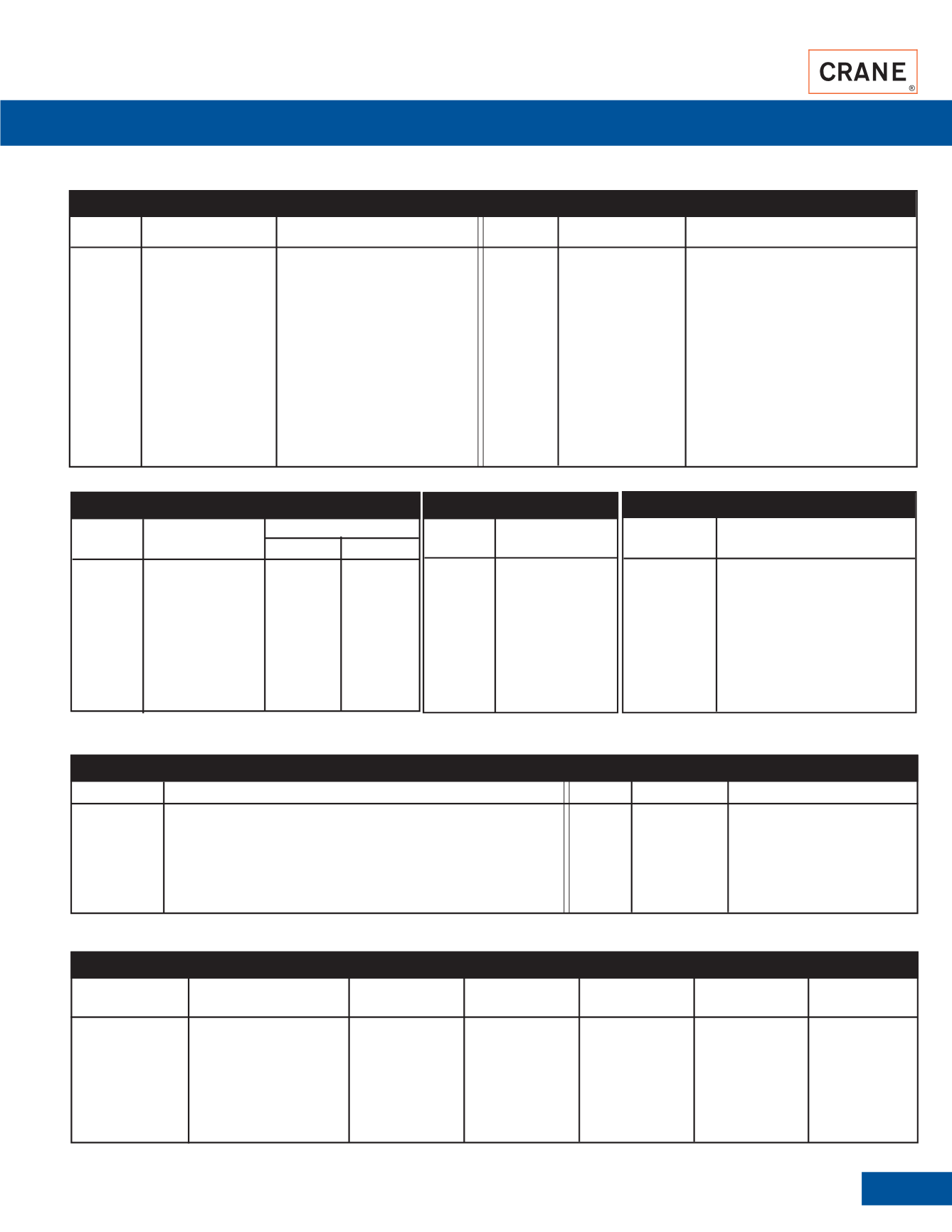

Standard trim (WettedParts)Materials

Typical

Body

Seal

Hinge

Spring

Stop

FigureNo.

&Plate

Pin

Pin

Retainer

BMF

Al.Bronze

Buna-N

316S.S.

316S.S.

316S.S.

316S.S.

CMF

316Stainless

Buna-N

316S.S.

316S.S.

316S.S.

316S.S.

CPF

316Stainless

316Stainless

316S.S.

Inconel 600

316S.S.

316S.S.

CVF

316Stainless

Viton-B

®

316S.S.

Inconel 600

316S.S.

316S.S.

EPF

410Stainless

410Stainless

410S.S.

Inconel 600

410S.S.

410S.S.

SMF

CarbonSteel

Buna-N

316S.S.

316S.S.

316S.S.

Steel

SPF

CarbonSteel

CarbonSteel

316S.S.

Inconel 600

316S.S.

Steel

SVF

CarbonSteel

Viton-B

®

316S.S.

Inconel 600

316S.S.

Steel

Ordering

Material

Specification

Letter

B AluminumBronze

ASTMB148,Alloy 952

AB Ni-AluminumBronze ASTMB148,Alloy 958

C 316StainlessSteel

ASTMA351, Gr.CF-8M

E 410StainlessSteel

ASTMA217, Gr.CA15 (12%Cr)

F

Alloy 20

ASTMA351, Gr.CN7M

G LowTemp.C.S.

ASTMA352, Gr. LCB

H Cast Ironwith

ASTMA126, class 40

Al.Br.Plates

ASTMB148, (952)

K Hastelloy

®

C

A494, Gr.CW12MW

L

C12AlloySteel

ASTMA217, Gr.C12 (9%Cr)

M Monel

ASTMA494, Gr.M30C

S CarbonSteel

ASTMA216, Gr.WCB

(Std.andCEnon-impact tested)

S1

CarbonSteel

ASTMA216, Gr.WCB

(CE impact tested)

Ordering Material

Specification

Letter

T

317S.S.

ASTMA351, Gr.CG-8M

U WC6AlloySteel

ASTMA217, Gr.WC6 (1

1

⁄

4

%Cr)

V 347S.S.

ASTMA351, Gr.CF-8C

Y C5AlloySteel

ASTMA217, Gr.C5 (5%Cr)

Z

WC9AlloySteel

ASTMA217, Gr.WC9 (2

1

⁄

2

%Cr)

CA Duplex

ASTMA351, Gr.CD4MCu

DZ 22%Duplex

UNSS31803,ASTMA890, Gr. 4A

EA 254SMOStainless UNSS31254, (ASTMCK3MCuN)

FN Inconel

®

625

ASTMA494, Gr.CW-6MC

GC LCC LowTemp.Steel

ASTMA352, Gr. LCC

TT Titanium

ASTMB367, Gr.C2/ASTMB348, Gr 2r

EB 25%Super Duplex

ASTMA890, Gr 6A/A351, Gr.CD3MWCuN

Mod.No. APITrimNo. Material Description

-169

1

Type 410

-491

5

Hard Faced

-131E

8

F6 andHardFaced

-772

9

Monel

-233

10

Type 316

-385E

12

316 and Hard Faced

Designation

Configuration

No.

None (Blank) Wafer Style, inserted between

mating flangeswith studs

spanning entire length

1

Lug designw/threaded holes

bolted from each end

2

Lug designwith through-bolt holes

to protect studs

3

Double flanged designwith valve

flanges bolted to individual

line flanges