19

T: 936-588-8350 • F: 936-588-8381 • www.craneenergy.com

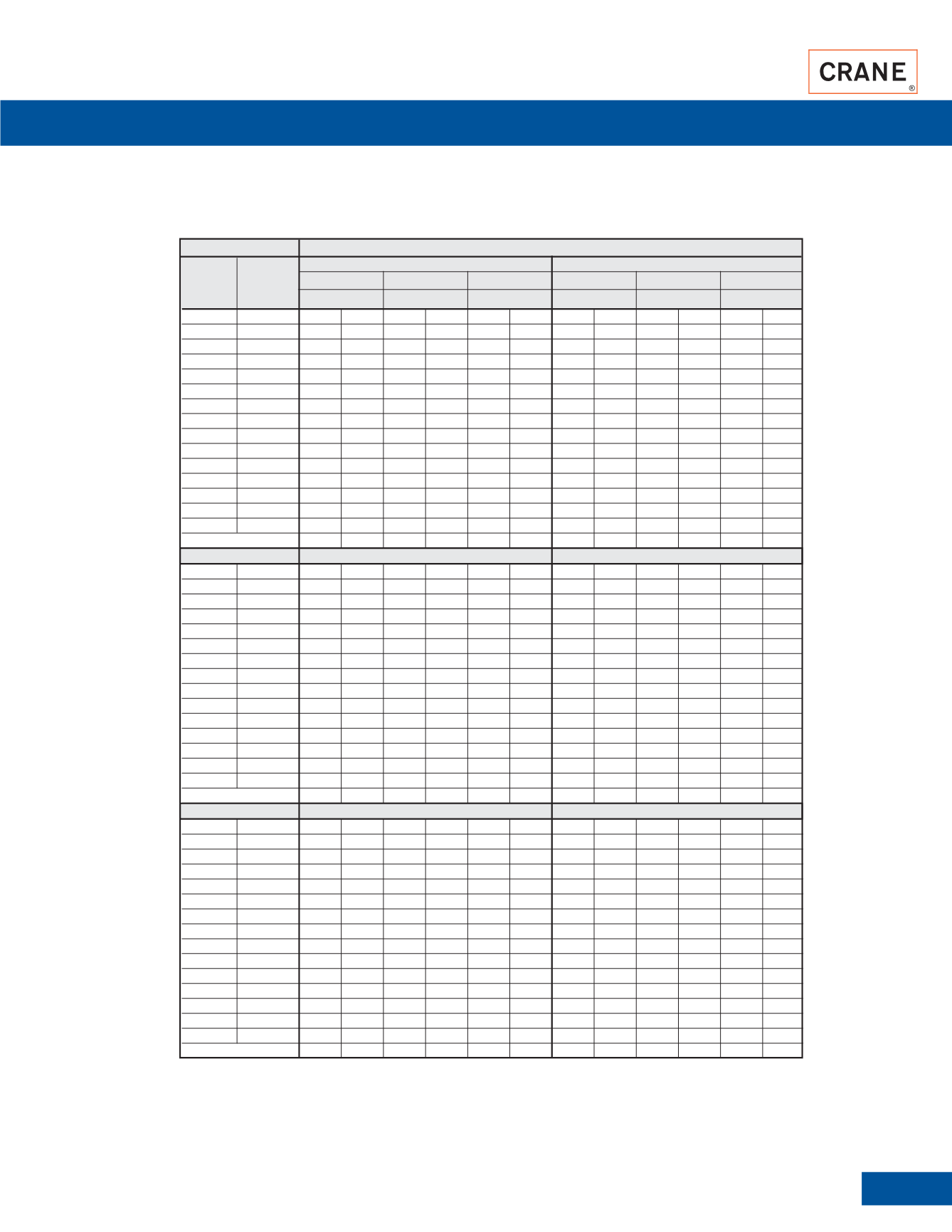

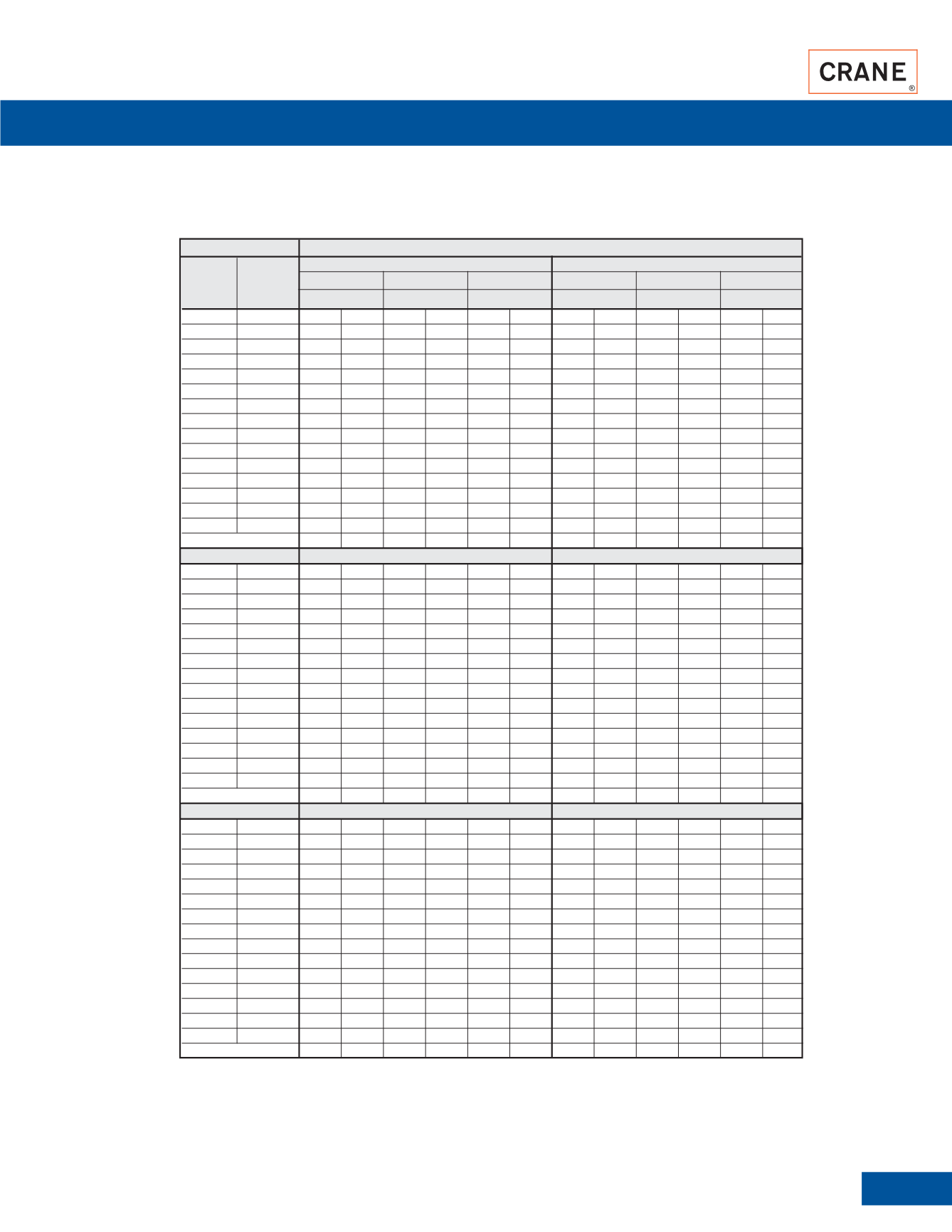

Duo-ChekValves

Technical Data

-29 to 0 -20 to 32 260.5 3705 -

-

253.1 3600 433.8 6170 -

-

421.8 6000

0 to 38 32 to 100 260.5 3705 260.5 3705 253.1 3600 433.8 6170 433.8 6170 421.8 6000

93

200

238.7 3395 238.7 3395 217.6 3095 397.5 5655 397.5 5655 362.7 5160

149

300

229.9 3270 229.9 3270 196.5 2795 383.1 5450 383.1 5450 327.6 4660

204

400

222.9 3170 222.9 3170 180.7 2570 371.2 5280 371.2 5280 300.9 4280

260

500

212.0 3015 212.0 3015 168.0 2390 353.3 5025 353.3 5025 279.8 3980

316

600

199.7 2840 199.7 2840 158.5 2255 332.5 4730 332.5 4730 264.3 3760

343

650

193.0 2745 193.0 2745 155.4 2210 321.6 4575 321.6 4575 258.7 3680

371

700

187.3 2665 187.3 2665 152.6 2170 311.1 4425 311.1 4425 254.5 3620

399

750

178.2 2535 178.2 2535 150.1 2135 297.4 4230 297.4 4230 250.3 3560

427

800

144.5 2055 144.5 2055 148.3 2110 241.1 3430 241.1 3430 247.5 3520

454

850

112.1 1595 112.1 1595 146.9 2090 186.6 2655 186.6 2655 244.6 3480

482

900

80.8 1150 80.8 1150 145.9 2075 134.6 1915 134.6 1915 243.2 3460

510

950

48.2 685 48.2 685 135.7 1930 80.5 1145 80.5 1145 226.4 3220

538

1000

30.2 430 30.2 430 127.9 1820 50.3 715 50.3 715 213.0 3030

HydrostaticShell Test

391.9 5575 391.9 5575 379.6 5400 652.0 9275 652.0 9275 632.7 9000

-29 to 0 -20 to 32 20.0 285 -

-

19.3 275 52.0 740 -

-

50.6 720

0 to 38 32 to 100 20.0 285 20.0 285 19.3 275 52.0 740 52.0 740 50.6 720

93

200

18.3 260 18.3 260 16.5 235 47.8 680 47.8 680 43.6 620

149

300

16.2 230 16.2 230 15.1 215 46.0 655 46.0 655 39.4 560

204

400

14.1 200 14.1 200 13.7 195 44.6 635 44.6 635 36.2 515

260

500

12.0 170 12.0 170 12.0 170 42.5 605 42.5 605 33.7 480

316

600

9.8 140 9.8 140 9.8 140 40.1 570 40.1 570 31.6 450

343

650

8.8 125 8.8 125 8.8 125 38.7 550 38.7 550 30.9 440

371

700

7.7 110 7.7 110 7.7 110 37.3 530 37.3 530 30.6 435

399

750

6.7 95 6.7 95 6.7 95 35.5 505 35.5 505 29.9 425

427

800

5.6 80 5.6 80 5.6 80 28.8 410 28.8 410 29.5 420

454

850

4.6 65 4.6 65 4.6 65 22.5 320 22.5 320 29.5 420

482

900

3.5 50 3.5 50 3.5 50 16.2 230 16.2 230 29.2 415

510

950

2.5 35 2.5 35 2.5 35 9.5 135 9.5 135 27.1 385

538

1000

1.4 20 1.4 20 1.4 20 6.0 85 6.0 85 25.7 365

HydrostaticShell Test

31.6 450 31.6 450 29.9 425 79.1 1125 79.1 1125 77.3 1100

ASMEB16.34Pressure-TemperatureRatings

Steel andStainlessSteel

Temperature

MaximumNon-ShockServicePressure, psi and kg/cm

2

(ASMEB16.34)

Class 150

Class 300

°C °F

Steel

(1) (2)

Steel

(1) (3)

316SS Steel

(1) (2)

Steel

(1) (3)

316SS

kg/cm

2

psi kg/cm

2

psi kg/cm

2

psi kg/cm

2

psi kg/cm

2

psi kg/cm

2

psi

Notes:

For latest information please refer toASMEB16.34.

(1)

Permissible, but not recommended for prolonged use above 800°F (427°C)

(2)

CE impact testedmaterial and standard non impact testedmaterial

(3)

CE non impact testedmaterial

-29 to 0 -20 to 32 104.0 1480 -

-

101.2 1440 156.1 2220 -

-

151.8 2160

0 to 38 32 to 100 104.0 1480 104.0 1480 101.2 1440 156.1 2220 156.1 2220 151.8 2160

93

200

95.6 1360 95.6 1360 87.2 1240 143.1 2035 143.1 2035 130.8 1860

149

300

92.1 1310 92.1 1310 78.7 1120 138.1 1965 138.1 1965 118.1 1680

204

400

88.9 1265 88.9 1265 72.1 1025 133.6 1900 133.6 1900 108.3 1540

260

500

84.7 1205 84.7 1205 67.1 955 127.2 1810 127.2 1810 100.9 1435

316

600

79.8 1135 79.8 1135 63.3 900 119.9 1705 119.9 1705 95.3 1355

343

650

77.3 1100 77.3 1100 62.2 885 111.8 1650 111.8 1650 93.1 1325

371

700

74.5 1060 74.5 1060 61.2 870 112.5 1590 112.5 1590 91.7 1305

399

750

71.4 1015 71.4 1015 60.1 855 106.9 1520 106.9 1520 90.0 1280

427

800

58.0 825 58.0 825 59.4 845 86.8 1235 86.8 1235 88.9 1265

454

850

45.0 640 45.0 640 58.7 835 67.1 955 67.1 955 88.2 1255

482

900

32.3 460 32.3 460 58.3 830 48.5 690 48.5 690 87.5 1245

510

950

19.3 275 19.3 275 54.5 775 28.8 410 28.8 410 81.5 1160

538

1000

12.0 170 12.0 170 51.0 725 17.9 255 17.9 255 76.6 1090

HydrostaticShell Test

156.4 2225 156.4 2225 152.9 2175 235.5 3350 235.5 3350 228.5 3250

°C °F

Class 1500

Class 2500

°C °F

Class 600

Class 900