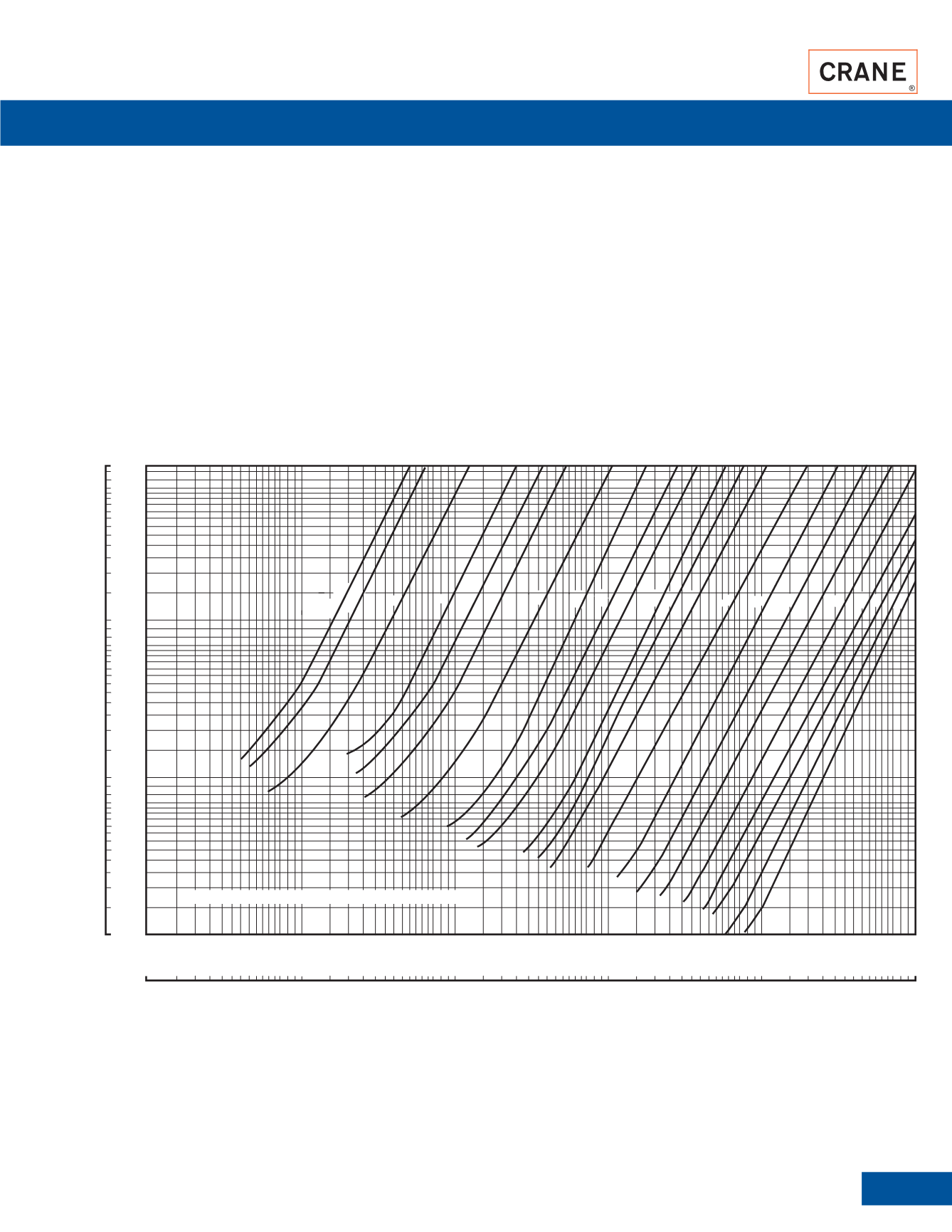

21

T: 936-588-8350 • F: 936-588-8381 • www.craneenergy.com

Duo-ChekValves

0.1

10

20

30

40

50

60

70

100

200

300

400

500

600

700

1000

2000

3000

4000

5000

6000

7000

10000

20000

30000

40000

50000

60000

70000

100000

200000

300000

400000

500000

600000

700000

1000000

0.2

0.3

0.5

0.6

0.7

1.0

0.6

1.3

1.9

2.5

3.2

3.8

4.4

6

13

19

25

32

38

44

63

126

189

252

315

378

442

631

1262

1892

2523

3154

3785

4416

6308

12616

18924

25232

31540

37848

44156

63080

0.4

2.0

3.0

4.0

5.0

6.0

7.0

10

20

30

40

50

60

70

100

0.03

0.06

0.09

HEAD LOSS INMETERSOFWATER

GALLONSPERMINUTE

LITERSPERSECOND

HEAD LOSS IN FEETOFWATER

0.12

0.15

0.18

0.21

0.3

0.6

0.9

1.2

1.5

1.8

2.1

3.0

6.1

9.1

12.2

15.2

18.3

21.3

30.5

2" VALVE

3"

2 1/2"

5"

6"

8"

10"

12"

14"

16"

18"

20"

24"

30"

36"

42"

48"

54"

60"

66"

72"

LOSSESSHOWNBASESONWATERAT 60°FWITHSP. GR. OF 1.0

4"

Technical Data

PressureLoss Information

• The curves showpressure drops availablewith standard torque springs

and theDuo-Chek in horizontal flow.

• Duo-Chek valves should be installed in horizontal flowwithpins vertical

for best performance.For other installations, contact the factory.

• Eachpiping system has aunique geometrywhich should be evaluated

whenever the liquidmedia velocity exceeds 8 feet/second (2.4m/sec)

througha swageor expansion (15° or greater includedangle) directly

upstream of the valve.Wherepracticable,

formaximumservice life,

andbasedonactual service,

aminimum of one (1) to five (5) pipe

diameters distance should bemaintainedbetween the valve and the

pump discharge and pipe fittings (swages or expansion).

• Systemswith drastic flow decelerationsmay require higher torque

springs for faster valve response and to reducewater hammer.Please

consult the factory.

• We can evaluateDuo-Chek valves relative to your system behavior.