V5011PTWO-WAYTHREADEDGLOBEVALVE

APEN0H-003TW01A0604

6

Mounting

The preferred valvemounting position iswith the stem

vertical. For steam applications,mount with the stem at a 45

degree angle. Do not mount the valvewith the stemmore

than 90 degrees from the vertical (pointing lower than

horizontal). Scale and foreignmaterial can collect, scoring

the stem and causing packing leakage. Protect the stem from

damage due to bending or scratching.

IMPORTANT

1. Before installing linkageand actuator, make sure that

the valve stem operates freely. Impaired stem operation

can indicate that the bodywas twisted or the stemwas

bent. Either of these conditions can require valve

replacement.

2. Align pipes squarelywith valve at each end connections.

3. If the pipes are forced into the valve, the body can

become twisted and improper seating can result.

4. Apply pipe dope sparingly.

5. Be careful to prevent pipe debris, such as chips and

scale, from entering the piping because thismaterial can

lodge in the seat and prevent proper closing.

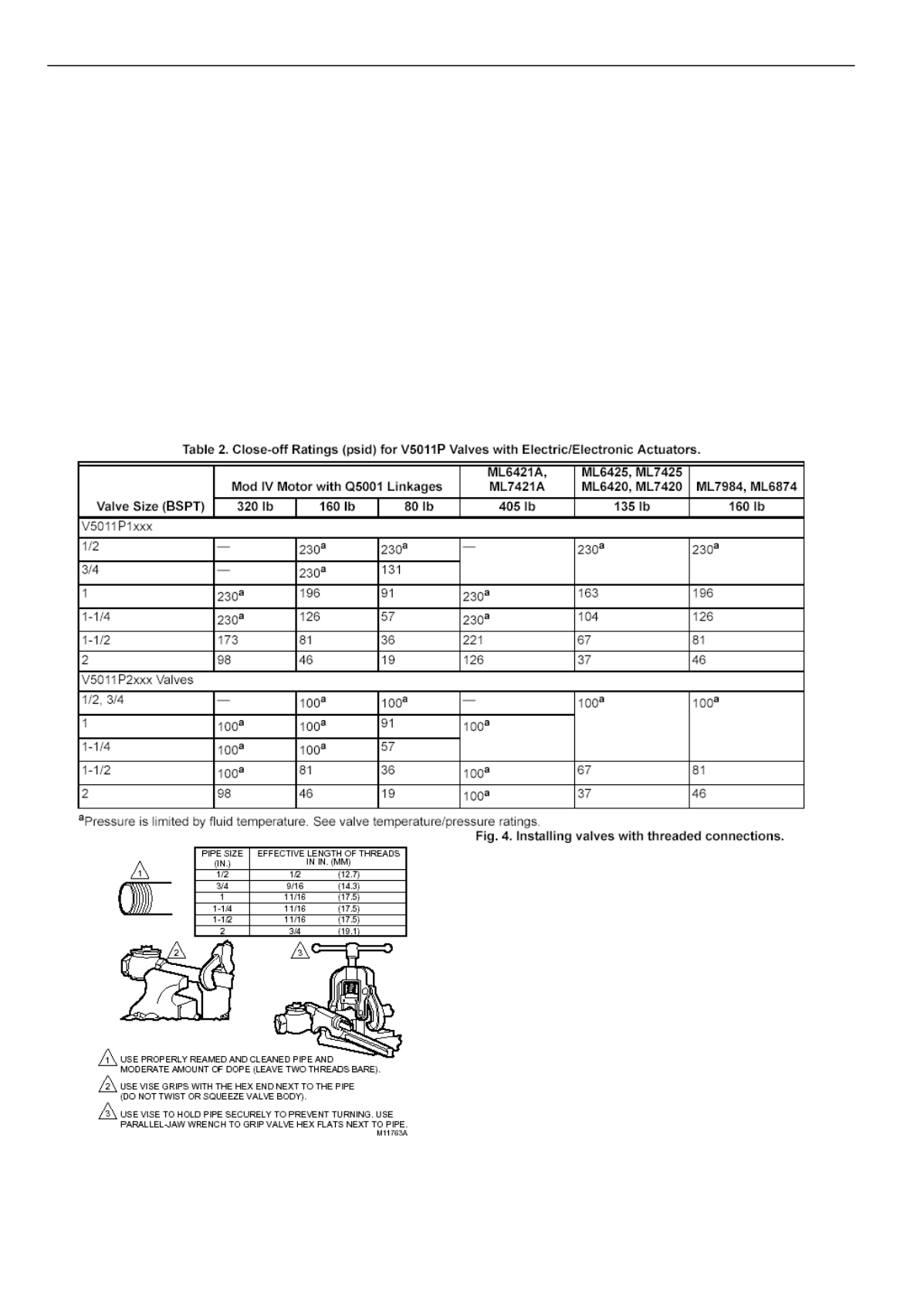

NOTE: Threading on threaded bodies conform toBSPT.

Refer to the table inFig. 4 for valve pipe sizes and thread

lengths. Fig. 4 also shows two effectivemethods of holding

the valve and pipewhen attaching it. Refer to installation

information furnishedwith the linkage andmotor when

installing these controls.