09

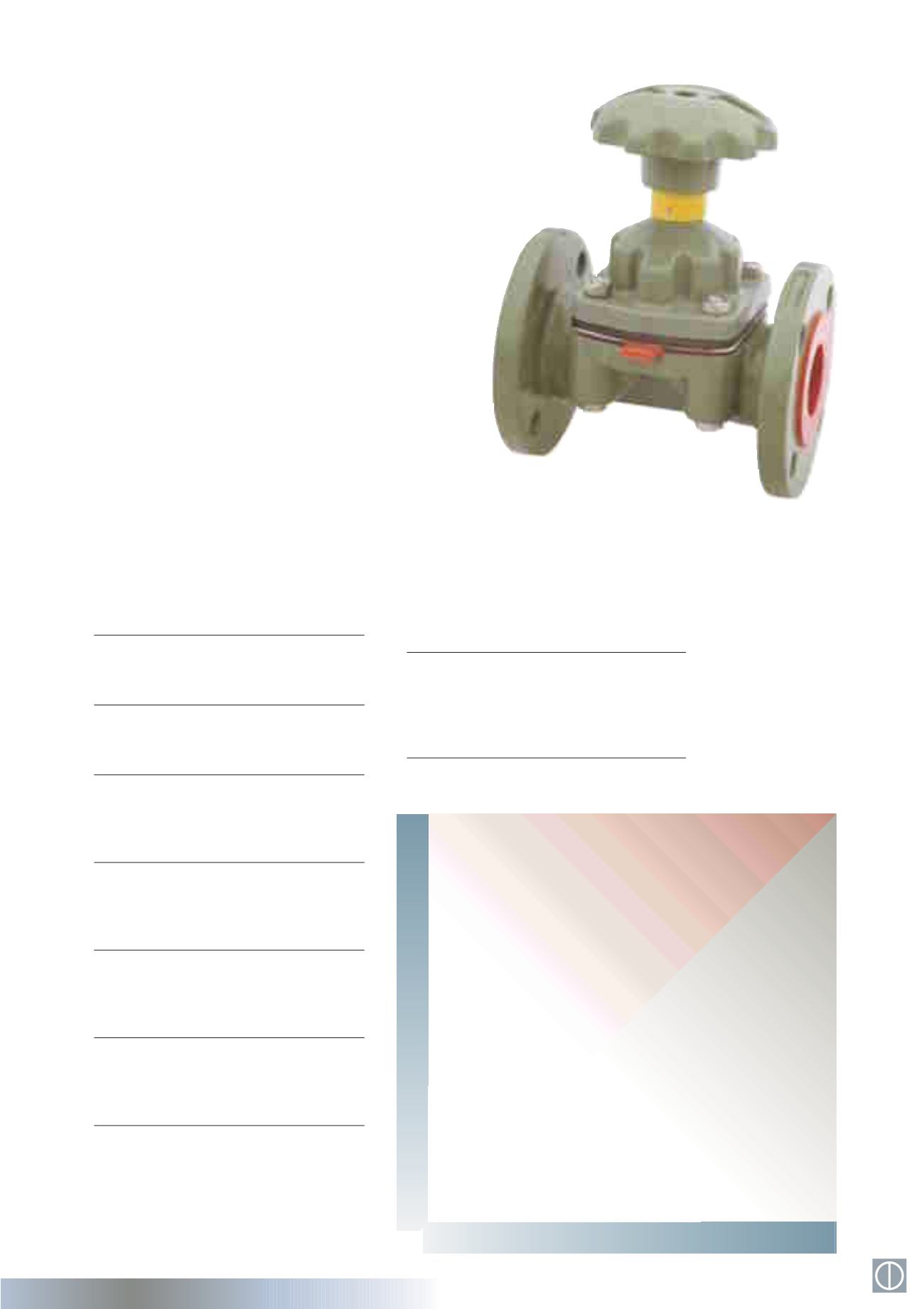

Saunders Environmental Protection

Hard Rubber – NR/HRL

Used for salts in water, dilute mineral acids,

chlorine water, de-ionised water, plating

solutions and potable water.

Soft Butyl Rubber – IIR/BL

Good for corrosive and abrasive slurries,

mineral acids and acidic slurries.

Glass

Used inmulti-process chemical plants on

acids and solvents.

Polypropylene – PP

Main applications include mineral acids,

salts in water, water and effluent treatment

chemicals.

Ethylene tetrafluoroethylene – ETFE

Suitable for strong acids, salts in water at

higher temperatures, solvents at medium

temperature.

Perfluoroalkoxy – PFA

Most suitable for concentratedmineral

acids at high temperature, aromatic,

aliphatic and chlorinated solvents.

Polytetrafluoroethylene – PTFE

Most suitable for concentratedmineral

acids at high temperature, aromatic,

aliphatic and chlorinated solvents.

Soft Natural Rubber - AA/SRL

High abrasion resistance.

Suitable for use on powders, abrasive

slurries, clays, coal dust, dry fertilizer,

gypsum.

Neoprene – NRL

Particularly suitable for animal, vegetable,

fatty oils and greases. Abrasion resistance

over wide pH range –used for aggressive

slurries.

ValveBodyLiningMaterials–Visual ProcessResistanceGuide

A B R A S I O N R E S I S TA N C E

High

CORROS I ON / CH EM I CA L R E S I S TANC E

High

ValveBody Linings for Saunders Valves

PTFE/PFA

ETFE

HRL

PP

Butyl

Neoprene

Glass

AANatural

Saunders environmental protective coating has been

developed specifically to provide unrivalled corrosive

resistance in the industrial processing industry, the new

protective coating utilises Du Pont’s Tefzel™

(Ethylenetetraflouroethylene) material.

The green Tefzel™ coating is applied before the injection

moulding of the Perfluoroalkoxy (PFA) or

Ethylenetetraflourorethylene (ETFE) lining, using an

electrostatic powder coatingmethod. By coating the valve

body, bonnet and hand wheel, both internal and external

corrosive protection is maximised providing peace of mind in

extreme corrosive material processing applications.

Available in DN 20-100 with a PFA lining and DN 20 – 150 in

the ETFE lined option.