Crane Process Flow Technologies

08

SaundersA TypeDiaphragmValves

Materials of Construction–ValveBodies

Rubber lined

body data

Plastic lined

body features

SG ironbody – high

mechanical strength

SG ironbody –

mechanically supports

plastic lining

Liningprotected from

ultraviolet (UV)

Injectiongate to side of

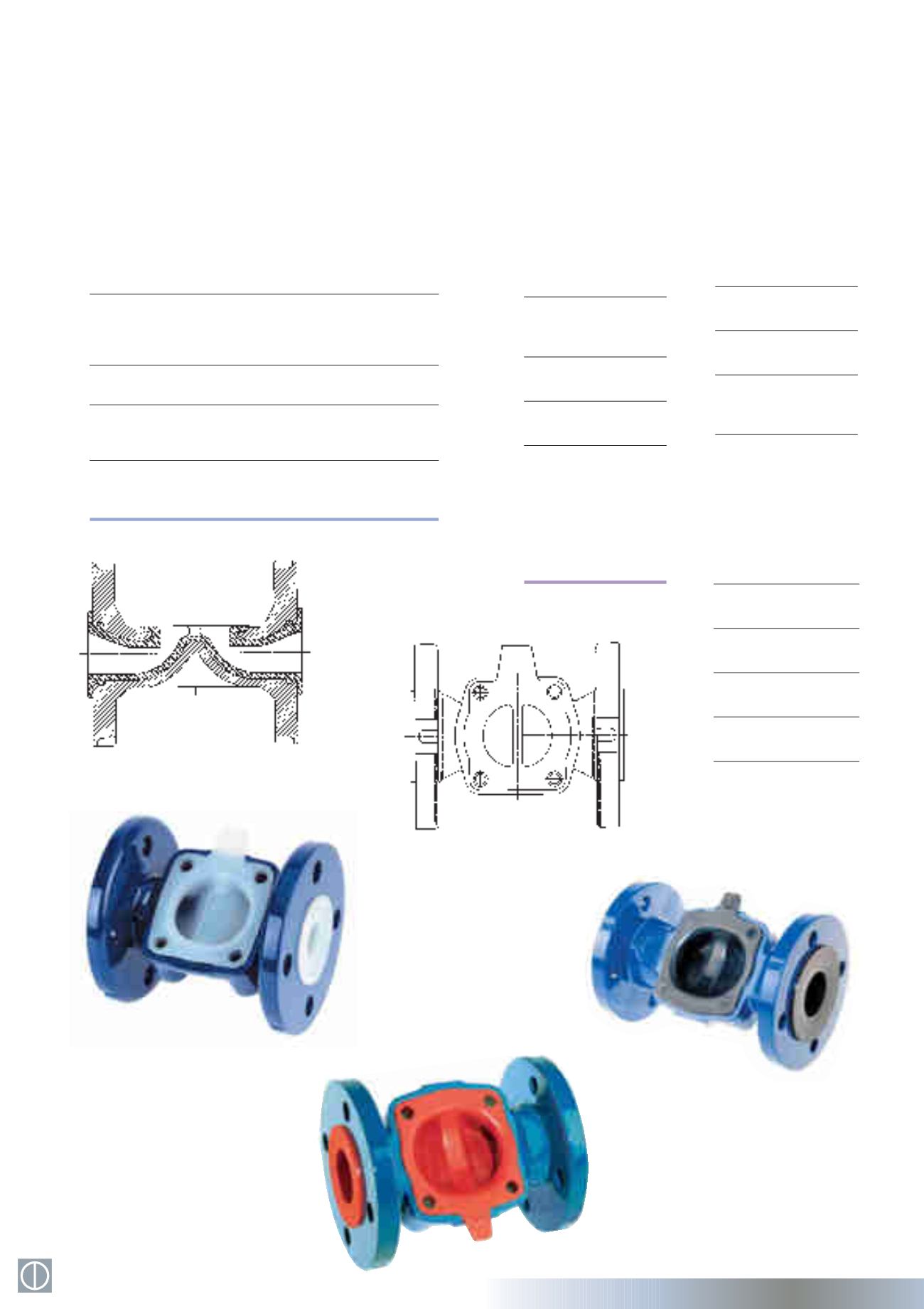

weir flangemeans:–

Smoothweir for

diaphragm sealing and

zero leakage

Lining lock-onweir flange

and in-bore inlet

Lining thickness range

3 –5mm (DN20–DN150)

Soft rubber linings

Butyl (Isobutylene

isoprene), 60–66° IRHD

Hard ebonite rubber

HRL, 75–85° ShoreD

Lining thickness range

2–4.5mm

(DN20–DN350)

CAST IRON

BS EN 1561

GJL–250

Flanged

DN15–DN500

SG IRON

BS EN 1563

GJS–450–10

Screwed

DN15–DN50

BS EN 1563

GJS–400–18

Flanged

DN15–DN150

GJS–400–18–LT

CASTSTEEL

ASTMA216WCB Flanged

DN15–DN100

BRONZE

BS EN 1982

CC491K–GS

Screwed

DN15–DN50

BS EN 1982

CC492K–GS

Flanged

DN15–DN100

STAINLESSSTEEL

BS 3100

316C16

Screwed

DN15–DN50

BS 3100

316C16

Flanged

DN15–DN150

Valve body lining –

production tests

StandardUnlinedBodyMaterial

Lined valveweir plan

All Saunders lined

valves have eachbody

individually tested for

lining integrity.

Glass lining –

Spark test 10kV ac

Rubber, Butyl –

Spark test 14kV ac/dc

Rubber, HRL –

Spark test 17kV ac/dc

Plastic lined –

Spark test 20kV ac/dc

Lined valve body section

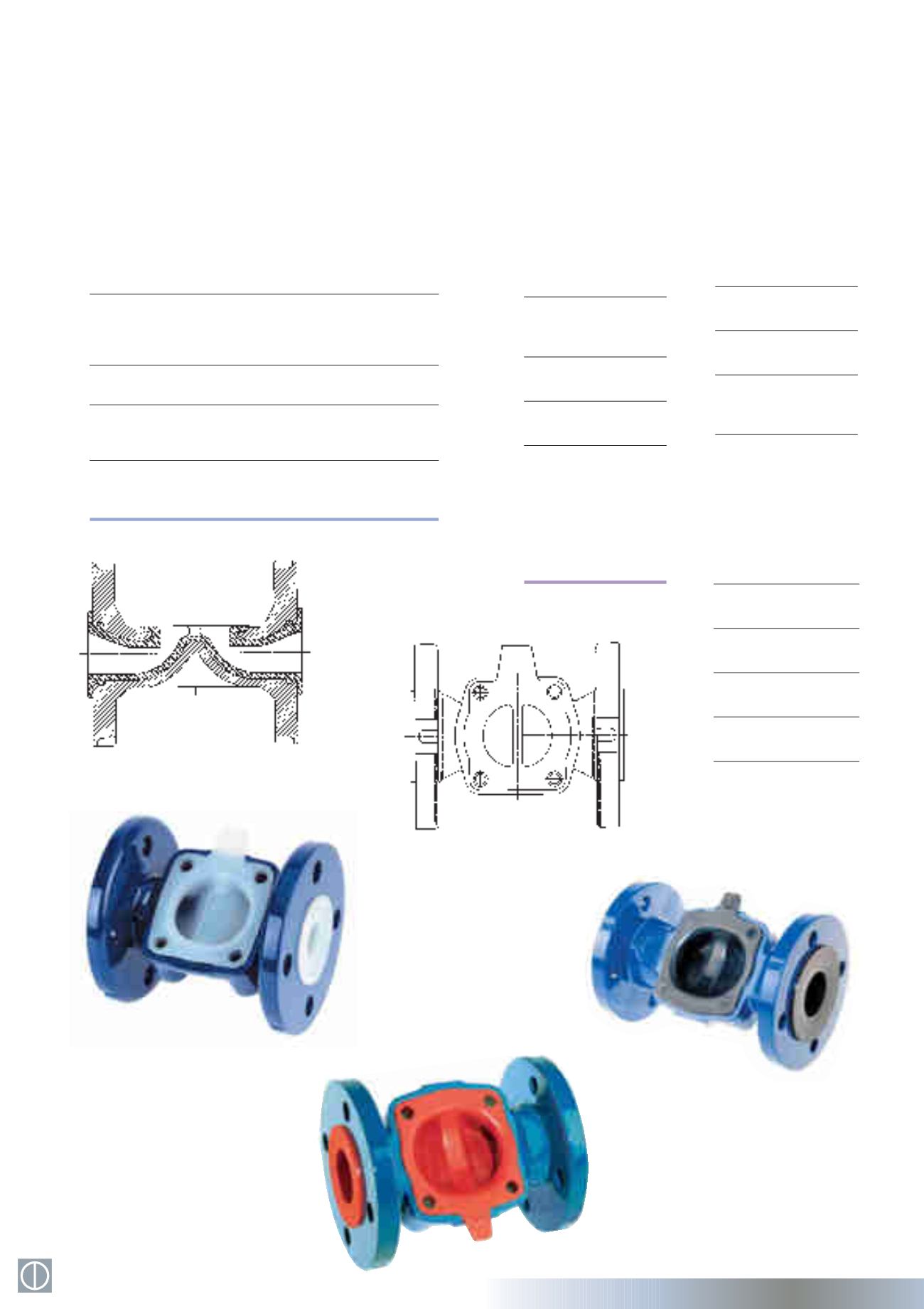

A Type valve body

ETFE lined

A Type valve

body hard

rubber lined

A Type valve body

PFA lined