| |

|

| |

|

|

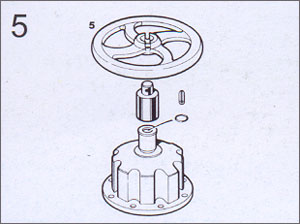

Handwheel:

Comfortable handwheel for fast easy operation, saves time and effort.

Other methods of operation- Pneumatic and electric actuators - versatility to match individual needs throughout the plant, without over investment. Ask for information on our Saunair ES actuators. |

2. |

Indication:

Clear, bright yellow valve position indicator confirms valve postion at a distance to save walking (or climbing) time. |

|

Stem:

Designed to reduce friction for low operating torque. |

4. |

Finish :

Phosphate and alkyd paint finish resists environmental attack, reduces need for painting. |

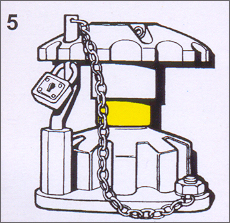

5. |

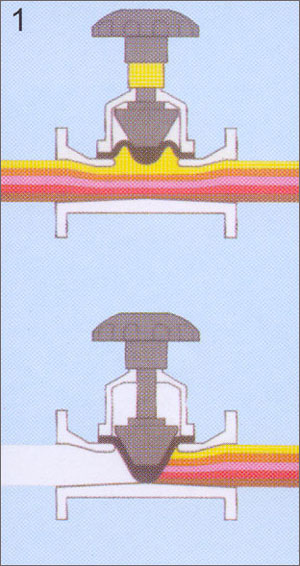

Sealing :

Operating mechanism (stem and compressor) seald from service and atmosphere, avoide the need for exotic metals. |

6. |

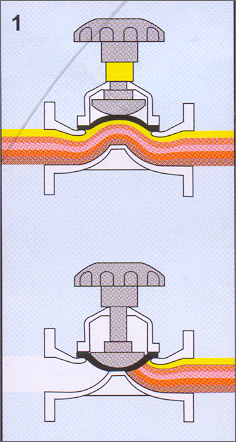

Diaphragms:

Tough, resilient diaphragms, with choice of grade to match the service, give 100% leaktight performance and protect working parts from line fluids. No leaks mean no money wasted. Diaphragm grades include natural and synthetic rubber mixes, nitrile, polychloroprene, hypalon, viton and ethylene propylene, Saunders 50 years of elastomer technology ensures that correct selection means long life for minimuuum running costs.

Body End connections:

Screwed and flanged end connectioons suit UK, European and USA specificaatioons to avoid planning problems. |

7. |

Linings:

Body linings prevent corrosion - without high capital outlay.

|

| |

|

Valve flow :

Smooth bore, straight -through body, gives non- turbulent flow to minimise wear from abrasion and allows rodding though when sludges 'set' in the pipeline - saving dismantling |

|

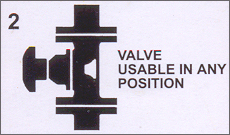

Valve usable in any position: For greater planning flexibility and ease of access. |

|

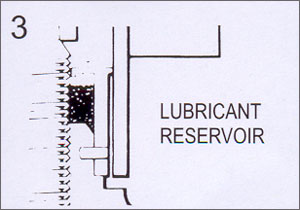

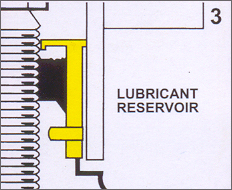

Lubrication:

Bonnet assembly lubricated for long life. Needs no grease. The indicator lip seal stops the ingress of dust, dirt and atmosphere. |

|

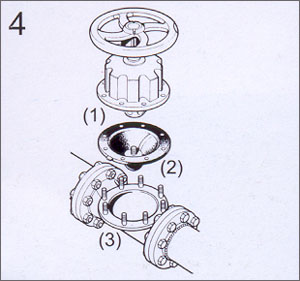

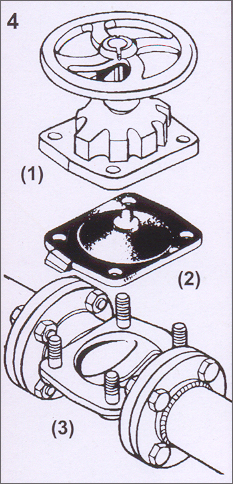

Maintenance:

Three part design bonnet (1), diaphragm (2) body (3) means the diaphragm is replaced with the body in the pipeline, no gasket costs or pipeline disturbance problems are involved. |

|

Bonnet Options:

Sealed to handle toxic or corrosive fluds with even greater safely. |

|

| |

|

| |

Body Linings and Coatings

(Base materials cast Grey and SG iron)

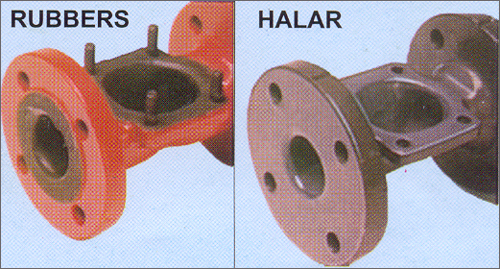

Rubbers:

(Hard, soft, butyl, neoprene)

Corrosives and abrasives handled with low initial outlay. Popularity of rubber linings results in exceptional availability.

Halar Coating:

Resists many industrial chemicals and additionally protects the exposed parts of valve bodies - to cut-out painting.

Borosilicate Glass Coating:

Purity, smooth flow (especially in viscous fluids) with great strength and resistance to chemical attack. (See main illustration).

Body Materials:

Cast iron, SG iron for strength and low cost on non-corrosive duties. Acid resisting bronze and gunmetal- long life in hostile, corrosive applications. Stainless steel- purity for services where profits depend on product protection.

|

| |

|

| |

|

| |

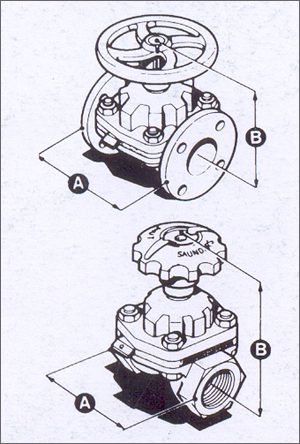

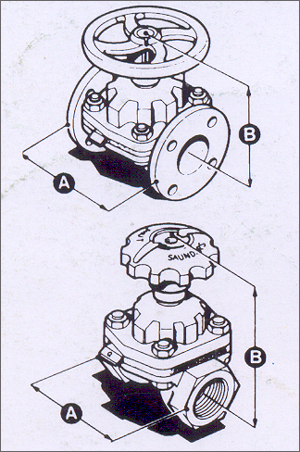

Type kb straight - through bore diaphragm valves basic details |

| |

|

| |

|

| |

| Valvesize |

Screwed Female Pipe Connections |

Flanged Pipe Connections |

(DN) |

A(mm) |

B(mm) |

A |

B(Max) |

|

|

|

Unlined |

Lined |

|

| 15 |

64 |

160 |

108 |

--- |

106 |

| 20 |

95 |

120 |

117 |

123 |

115 |

| 25 |

111 |

164 |

127 |

133 |

160 |

| 32 |

124 |

164 |

146 |

152 |

160 |

| 40 |

143 |

164 |

159 |

165 |

182 |

| 50 |

168 |

189 |

190 |

196 |

230 |

| 65 |

206 |

228 |

216 |

222 |

296 |

| 80 |

257 |

302 |

254 |

260 |

303 |

| 100 |

--- |

--- |

305 |

311 |

324 |

| 125 |

--- |

--- |

356 |

362 |

346 |

| 150 |

--- |

--- |

406 |

412 |

470 |

| 200 |

--- |

--- |

521 |

527 |

640 |

| 250 |

--- |

--- |

635 |

641 |

745 |

| 300 |

--- |

--- |

749 |

755 |

785 |

| 350 |

--- |

--- |

--- |

--- |

785 |

| Valves sizes DN 200-350 feature bonnet assembly design for ease of operation and low cost. At present stage of manufacture a non - rising handwheel unit is standard, Dimensions shown are for planning purposes and should not be used for manufacturing |

|

| |

|

| |

Weir type 'A' Diaphragm Valves |

| |

|

| |

|

| |

|

|

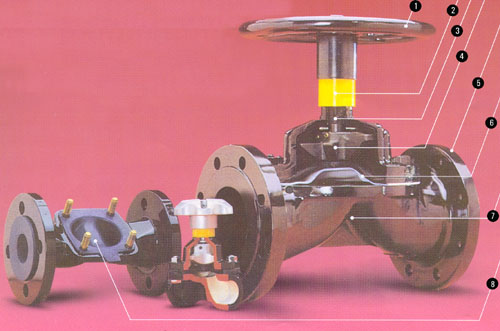

Handwheel :

Comfortable, easy to use for fast operation. Saves time and effort.

Other Methods of Operation-

Fast acting levers, pneumatic and electric actuators - versatility to match individual needs throughout the plant, without over investment. Ask for information on our Saunair ES actuators.

|

|

Indication-

Positive identification of valve position to save time and money.

|

|

Stem-

Designed to reduce friction for low operation torque. |

|

Sealing-

Operating mechanism (stem and compressor) sealed from service and atmosphere, avoids the need for exotic metals. |

|

|

|

Finish-

Phosphate and alkyd paint finish resists environmental attack, reduces need for painting.

Diaphragm-

Strong and resilient, giving positive shut-off. Designed to assist flow and completely isolate working parts from line fluids. |

|

|

6. |

Diaphragm Materials

Natural and synthetic rubbers, nitrile, butyl, viton, hypalon and ptfe faced. All give maximum processing security and, where required, food industry standards of hygiene. Special diaphragms are produced for fire fighting, tank cleaning and washdeck services to comply with international standards. |

7. |

Weir

Weir design reduces diaphragm travel for extended service and fine control.

Body End Connections-

Screwed, flanged and weld end connections suit UK, European, USA specifications to avoid planning problems. |

8. |

Linings

For purity abrasion and corrosion resistance, smooth flow- without exotic metal costs. |

| |

|

| |

|

Valve Flow -

Pocketless design for contamination free performance and smooth flow charcteristics. |

|

Valve usable in any position -

For greater planning flexibility and ease of access. In the horizontal plane at 15°angle (flanges can be drilled to suit) the valve is self - draining. |

|

Lubrication-

Bonnet assembly lubricated for long life. Needs no grease. The indicator lip seal stops the ingress of dust, dirt and atmosphere. |

|

Maintenance -

Three part design (bonnet(1), diaphragm (2), body (3),means the diaphragm is replaced with the body in the pipeline, no gasket costs or pipeline disturbance problems are involved. |

|

Bonnet options-

Padlocking to prevent expensive interference. Microswitch Model - for valve position indication systems. Sealed to handle toxic or corrosive fludis with even greater safety. |

|

| |

| |

|

|

Body Linings and Coatings:

(Base materials cast Grey and SG iron with a special option of cast steel for glass and rubber linings).

Polypropylene:

Combines strength and abrasion resistance for long service on chemical processing, water treatment and effluents.

PVDF:

Resistant to most inorganic acids and bases - for high performance without exotic material costs. (See main illustration).

ETFE / PFA / PTFE:

High abrasion resistance for tough services especially in fine chemicals, pharmaceuticals and petrochemicals.

Halar Coating:

Resists many industrial chemicals and additionally protects the exposed parts of valve bodies- to cut out painting.

Rubbers:

(hard, soft, butyl, neoprene): Corrosives and abrasives handled with low initial outlay- Popularity of rubber linings results in exceptional availability.

Borosilicate Glass Coating:

Purty, smooth flow (especially on viscous fluids) with great strength and resistance to chemical attack.

Body Materials:

Cast iron, SG iron and cast steel for strength and low cost on non- corrosive duties.

Acid resisting bronze and gunmetal - long life in hostile, corrosive water applications.

Stainless steel - purity for services where profits depend on product protection.

Solid hard rubber and polypropylene - minimum weight combined with strength.

For other special lining material, please contact us.

|

|

|

| |

|

| |

Weir type "A" diaphragm valves basic details |

| |

|

| |

|

| |

| Valvesize |

Screwed Female Pipe Connections |

Flanged Pipe Connections |

(DN) |

A(mm) |

|

B(mm) |

A(mm) |

B(Max) |

|

CI, SG, MI |

SS, GM, ARB |

All Materials |

Unlined |

BS 5156

Lined |

|

| 8 |

48 |

48 |

59 |

--- |

--- |

--- |

| 10 |

48 |

48 |

68 |

--- |

--- |

--- |

| 15 |

64 |

64 |

91 |

108 |

114 |

100 |

| 20 |

83 |

83 |

94 |

117 |

123 |

100 |

| 25 |

108 |

95 |

115 |

127 |

133 |

100 |

| 32 |

121 |

114 |

152 |

146 |

152 |

150 |

| 40 |

140 |

133 |

164 |

159 |

165 |

160 |

| 50 |

165 |

152 |

187 |

190 |

196 |

180 |

| 65 |

--- |

--- |

224 |

216 |

222 |

214 |

| 80 |

--- |

--- |

233 |

254 |

260 |

220 |

| 100 |

--- |

--- |

--- |

305 |

311 |

300 |

| 125 |

--- |

--- |

--- |

356 |

361 |

375 |

| 150 |

--- |

--- |

--- |

406 |

412 |

430 |

| 200 |

--- |

--- |

--- |

521 |

527 |

507 |

| 250 |

|

--- |

--- |

635 |

641 |

588 |

| 300 |

|

--- |

--- |

749 |

755 |

683 |

| 350 |

--- |

--- |

--- |

749 |

755 |

893 |

| |

|

| |

|