| |

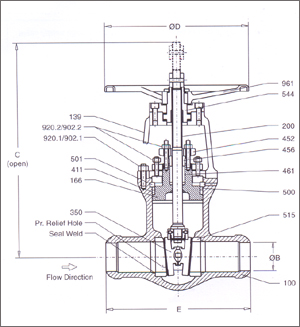

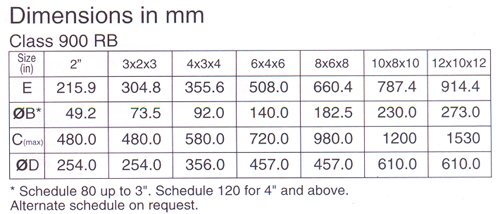

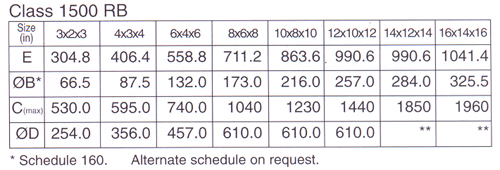

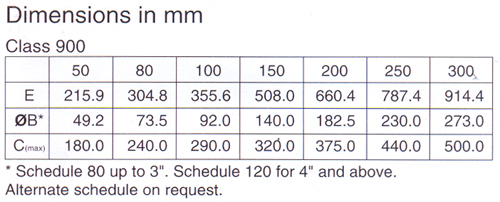

Gate Valves Cast Steel Pressure seal Buttwelded end Class 900, 1500 & 2500 50 - 400mm (2" - 16") |

| |

|

| |

Applications |

| |

|

| |

• |

Power stations, general industry, process engineering |

• |

For water, steam, gas oil & other non - aggressive media |

• |

Further applications on request |

|

| |

|

| |

Operating Data |

| |

|

| |

• |

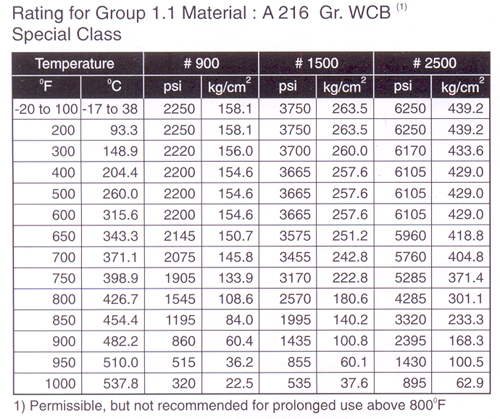

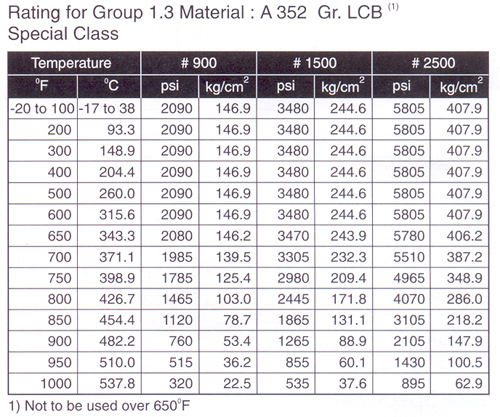

Pressure up to 431 bar (6250 psi) |

• |

Temperature up to +593° C/1100° F |

• |

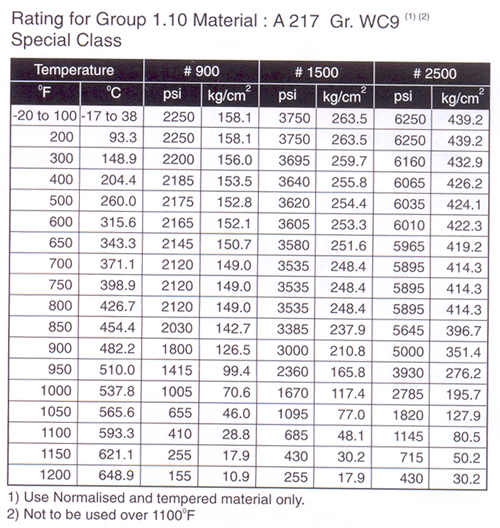

Pressure-temperature ratings as per ASME B 16.34 Standard class |

|

| |

|

| |

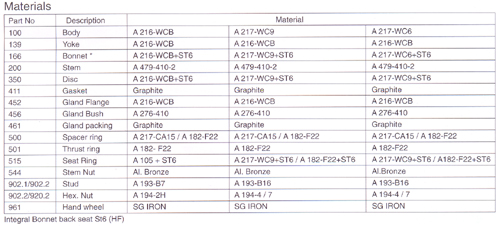

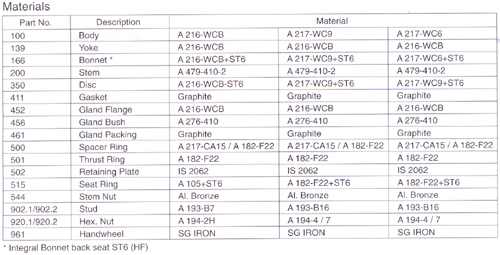

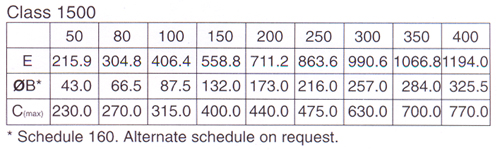

Materials |

| |

|

| |

| |

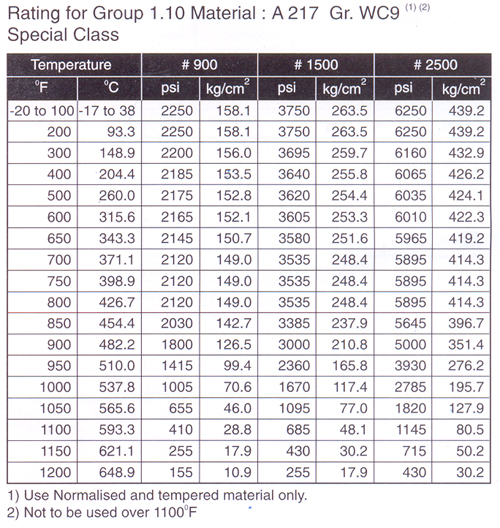

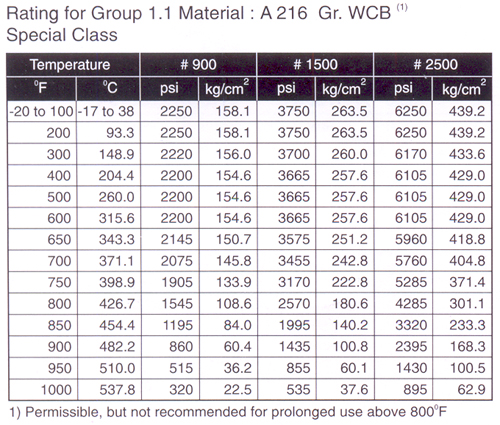

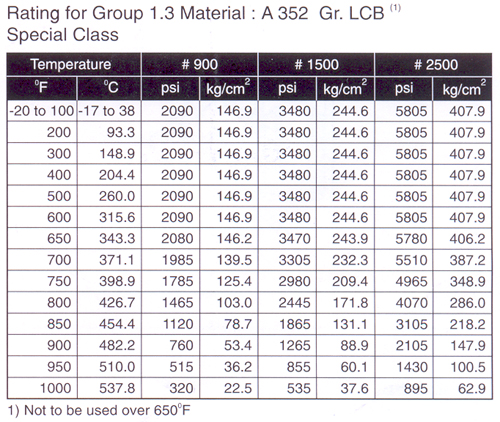

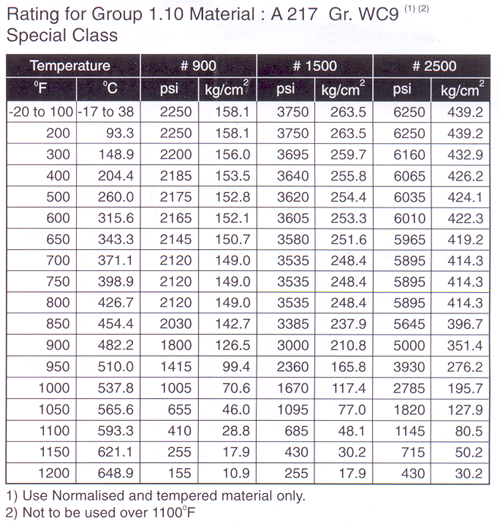

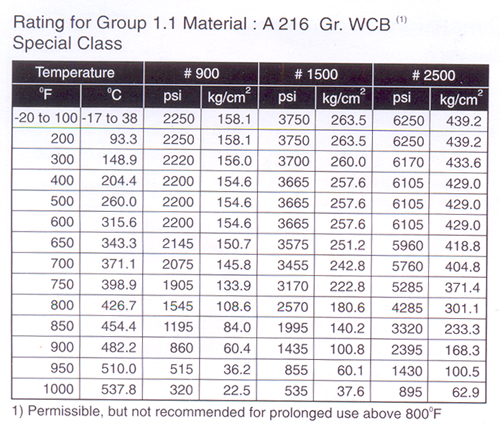

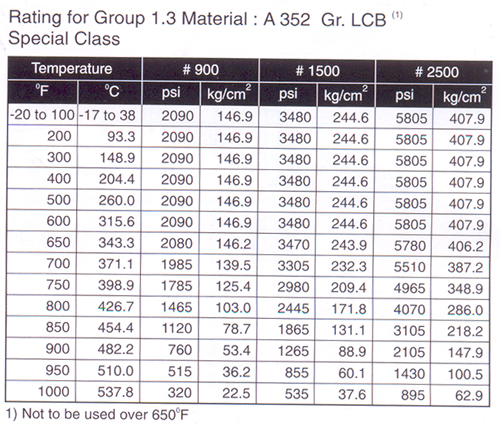

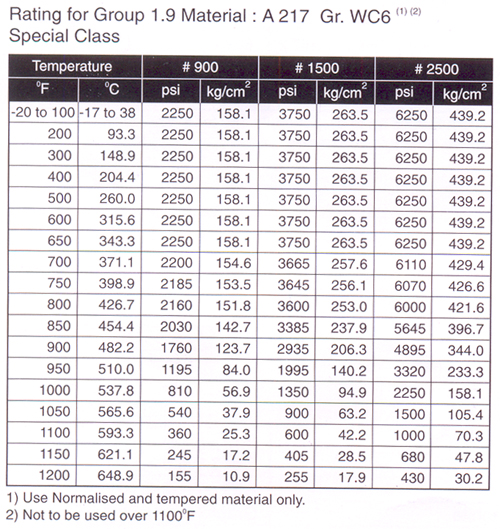

ANSI Standard Class (as per ASME B 16.34 ) |

• |

#900/1500/2500 - 216 WCB from 0°C to 425°C |

• |

#900/1500/2500 -A 217 WC6/WC9 from 0°C to 593°C |

• |

Other materials on request |

|

| |

|

| |

Design |

| |

|

| |

• |

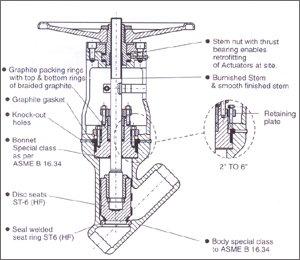

As per ASME B 16.34 |

• |

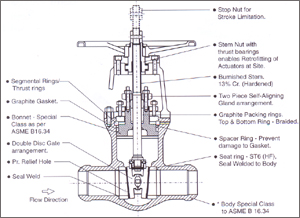

Pressure Seal Bonnet Design |

• |

Stellite hard - faced Seats & Disc surface |

• |

Graphite gaskets and graphite packings with Braided wiping rings |

• |

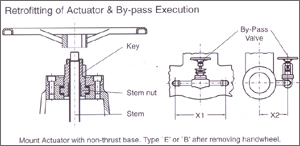

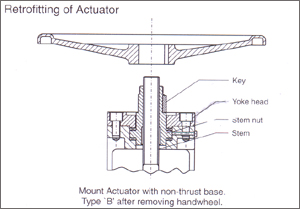

Direct retrofitting of Actuator |

• |

REduced bore |

• |

Double disc wedge design |

|

| |

|

| |

Design Specifications |

| |

|

| |

General valve design |

ASME B 16.34 Special class |

Pressure, temperature rating Buttweld end design |

ASME B 16.25 |

| End to end dimension /Face to face |

ASME B 16.10 |

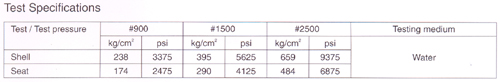

| Testing |

API 598 |

|

| |

|

| |

Variants on Request |

| |

|

| |

• |

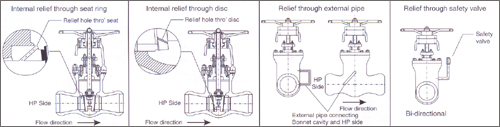

By - pass execution |

• |

Actuator execution / Gear execution |

• |

Bonnet pressure relief execution |

• |

Full bore execution |

• |

Position indicator |

• |

Locking arrangement |

• |

Other materials |

• |

Other executions |

|

| |

|

| |

Remarks |

| |

|

| |

Forged Valves leaflet no. |

7240.2/4-10 |

Pressure Seal Gate Valve leaflet no. |

7242. 2/5-10 |

Pressure Seal Globe Valve leaflet no. |

7243. 2/5-10 |

Cast Steel Gate Valve leaflet no. |

7244. 2/4-10 |

Cast Steel Globe Valve leaflet no. |

7245. 2/4-10 |

Cast Steel check Valve leaflet no. |

7246. 2/4-10 |

Operating instructions no. |

0500.80/02-18 G3 |

|

| |

|

| |

On all enquiries / orders please specify |

| |

|

| |

1 |

Type |

2 |

ANSI Pressure class |

3 |

Size |

4 |

Design pressure / temperature |

5 |

Operating pressure |

6 |

Operating temperature |

7 |

Differential pressure |

8 |

Material of construction |

9 |

Flow Medium |

10 |

Flow rate Min. / Max. |

11 |

Type of end connection |

12 |

Pipe schedule ID / OD |

13 |

Variants |

14 |

Leaflet no. |

15 |

Valve data sheet (if applicable) |

|

When ordering spares, indicate, valve serial number. |

|

| |

|

| |

Product features to our customer benefit |

| |

|

• |

Valves meets ASME 16.34 Special clas requirements |

• |

Unique Seat design ensures low operating torque |

• |

Compact Yoke design ensures low valve weight |

• |

Stop nut prevents over tightening of double disc gate |

• |

Designed to retrofit valve with Actuator at site without disassembly of pressure retaining parts |

|

| |

|

| |

|

| |

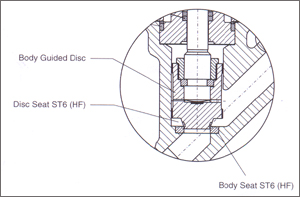

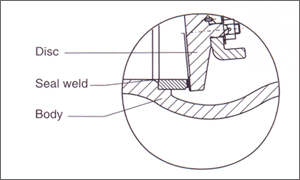

| Flow Seal |

• |

Fully stellited Body & Disc seats |

• |

Seat rings - seal welded to body |

• |

Lapped seat and wedge faces for leak tightness |

• |

Streamlined flow path ensures minimum pressure drop |

| Disc Design |

• |

Self aligning double disc arrangement ensures perfect seating |

• |

Wedging action ensures leak tightness |

• |

Leak tightness at low and high differential pressure |

• |

Extended disc wear life by possiblity of shim addition |

| |

|

| Stem wedge Connection |

• |

Strong stem - disc joint capable of withstanding higher operating |

|

| |

|

| |

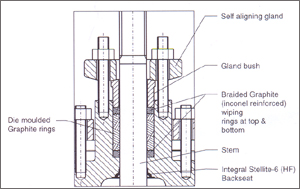

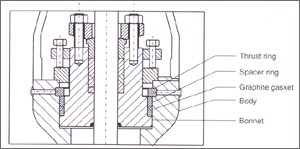

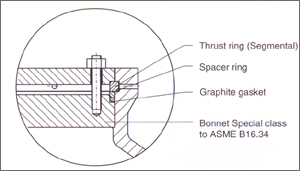

Pressure Seal Bonnet |

|

• |

Die moulded graphite gasket |

• |

Segmental ring arrangement with knock out hole ensures easy disassembly |

|

| |

|

| |

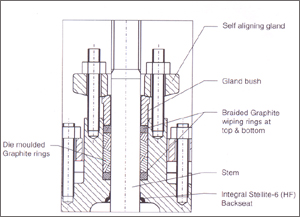

Gland Seal |

|

• |

Die moulded graphite rings ensures effective sealing to atmosphere |

| |

Top & bottom rings are braided graphite and inconel reinforced |

| |

Braided rings offer smooth wiping action thereby arresting graphite depletion |

| |

Smooth finished & polished stem and smooth stuffing box surfaces improve gland sealing life |

| |

Two piece self aligning gland arrangement |

• |

Integral hard faced back seat for maximum service life |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

Pressure Relief Arrangement :(Optional safety devices) |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

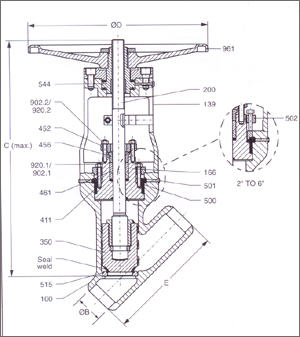

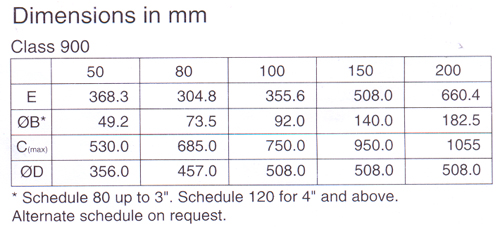

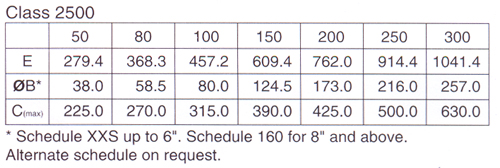

Globe Valves Cast Steel Pressure seal Butwelded end Classs 900, 1500 & 2500 50 - 200mm (2" - 8") |

| |

|

| |

Applications |

| |

|

| |

• |

Power stations, general industry, process engineering |

• |

For water, steam, gas oil & other non - aggressive media |

• |

Further applications on request |

|

| |

|

| |

Operating Data |

| |

|

| |

• |

Pressure up to 431 bar (6250 psi) |

• |

Temperature up to +593° C/1100° F |

• |

Pressure-temperature ratings as per ASME B 16.34 Standard class |

|

| |

|

| |

Materials |

| |

|

| |

| |

ANSI Standard Class (as per ASME B 16.34 ) |

• |

#900/1500/2500 - 216 WCB from 0°C to 425°C |

• |

#900/1500/2500 -A 217 WC6/WC9 from 0°C to 593°C |

• |

Other materials on request |

|

| |

|

| |

Design |

| |

|

| |

• |

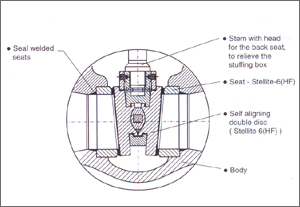

As per ASME B 16.34 |

• |

Pressure Seal Bonnet Design |

• |

Stellite hard - faced Seats & Disc surface |

• |

Graphite gaskets and graphite packings with Braided wiping rings |

• |

Direct retrofitting of Actuator |

|

| |

|

| |

Variants on Request |

| |

|

| |

• |

By - pass execution |

• |

Actuator execution / Gear Box execution |

• |

Position indicator |

• |

Locking arrangement |

• |

Other materials |

• |

Other executions |

|

| |

|

| |

Remarks |

| |

|

| |

Forged Valves leaflet no. |

7240.2/4-10 |

Pressure Seal Gate Valve leaflet no. |

7241. 2/5-10 |

Pressure Seal Globe Valve leaflet no. |

7243. 2/5-10 |

Cast Steel Gate Valve leaflet no. |

7244. 2/4-10 |

Cast Steel Globe Valve leaflet no. |

7245. 2/4-10 |

Cast Steel check Valve leaflet no. |

7246. 2/4-10 |

Operating instructions no. |

0500.80/02-18 G3 |

|

| |

|

| |

On all enquiries / orders please specify |

| |

|

| |

1 |

Type |

2 |

ANSI Pressure class |

3 |

Size |

4 |

Design pressure / temperature |

5 |

Operating pressure |

6 |

Operating temperature |

7 |

Differential pressure |

8 |

Material of construction |

9 |

Flow Medium |

10 |

Flow rate Min. / Max. |

11 |

Type of end connection |

12 |

Pipe schedule ID / OD |

13 |

Variants |

14 |

Leaflet no. |

15 |

Valve data sheet (if applicable) |

|

When ordering spares, indicate, valve serial number. |

|

| |

|

| |

Product features to our customer benefit |

| |

| |

|

• |

Valves meet ASME 16.34 Special class requirements |

• |

Compact yoke design ensures low valves weight |

• |

Designed to retrofit valve with Actuator at site without disassembly of pressure retaining parts |

• |

Stem lock arrangement ensures non - rotation of stem |

• |

'Y' Patter body minimizes pressure drop |

|

| |

|

| |

|

| Flow Seal |

• |

Fully stellited Body & Disc seats |

• |

Seat rings - seal welded to body |

• |

Valves will be with flow over disc to ensure leak tightness under high / full differential pressures. |

• |

Streamlined flow path ensures minimum pressure drop |

| Disc Design |

• |

Disc - Body guided, which stands unbalanced forces at high differential pressure |

• |

Stellite - 6 hard faced seating surface enhances sealing life |

| |

|

| Stem wedge Connection |

• |

Strong stem - disc joint capable of withstanding higher vibration during valve opening |

|

| |

|

| |

| Gland Seal |

| |

|

• |

Die moulded graphite rings ensures effective sealing to atmosphere |

• |

Top & bottom rings are braided graphite and inconel reinforced |

• |

Braided rings offer smooth wiping action thereby arresting graphite depletion |

| |

Smooth finished & polished stem and smooth stuffing box surfaces improve gland sealing life |

| |

Two piece self aligning gland arrangement |

• |

Integral hard faced back seat for maximum service life |

|

| |

|

| |

| Pressure Seal Bonnetl |

| |

|

• |

Die moulded graphite gasket |

• |

Segmental ring arrangement with knock - out hole ensures easy disassembly |

|

| |

|

| |

|

| |

Design Specifications |

| |

|

| |

General valve design |

ASME B 16.34 Special class |

Pressure, temperature rating |

|

Buttweld end design |

ASME B 16.25 |

| End to end dimension |

ASME B 16.10 |

| Testing standard |

API 598 |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

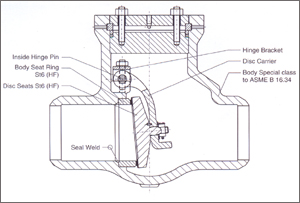

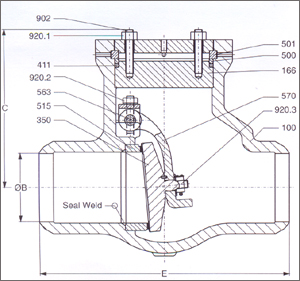

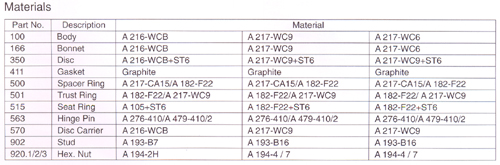

Swing Check Valves Cast Steel Pressure seal Butwelded end Classs 900, 1500 & 2500 50 - 40mm (2" - 16 ") |

| |

|

| |

Applications |

| |

• |

Power stations, general industry, process engineering |

• |

For water, steam, gas oil & other non - aggressive media |

• |

Further applications on request |

|

| |

|

| |

Operating Data |

| |

• |

Pressure up to 431 bar (6250 psi) |

• |

Temperature up to +593° C/1100° F |

• |

Pressure-temperature ratings as per ASME B 16.34 Standard class |

|

| |

|

| |

Materials |

| |

| |

ANSI Standard Class (as per ASME B 16.34 ) |

• |

#900/1500/2500 - 216 WCB from 0°C to 425°C |

• |

#900/1500/2500 -A 217 WC6/WC9 from 0°C to 593°C |

• |

Other materials on request |

|

| |

|

| |

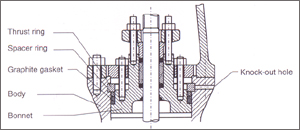

Design |

| |

• |

As per ASME B 16.34 |

• |

Pressure Seal Bonnet Design |

• |

Stellite hard - faced Seats & Disc surface |

• |

Graphite gaskets |

|

| |

|

| |

On all enquiries / orders please specify: |

| |

1 |

Type |

2 |

ANSI Pressure class |

3 |

Size |

4 |

Design pressure / temperature |

5 |

Operating pressure |

6 |

Operating temperature |

7 |

Differential pressure |

8 |

Material of construction |

9 |

Flow Medium |

10 |

Flow rate Min. / Max. |

11 |

Type of end connection |

12 |

Pipe schedule ID / OD |

13 |

Variants |

14 |

Leaflet no. |

15 |

Valve data sheet (if applicable) |

|

When ordering spares, indicate, valve serial number. |

|

| |

|

| |

Product features to our customer benefit |

| |

|

| |

| |

|

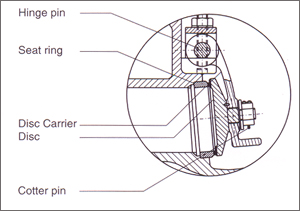

• |

Valves meet ASME 16.34 Special class requirements |

• |

Inside hinge pin mounted design - no leakage path to atmosphere |

• |

Self aligning free floating and non - rotating disc |

• |

Designed to open at low differential pressures |

|

| |

|

| |

Pressure Seal |

| |

| |

|

• |

Die - moulded graphite gasket |

• |

Segmental ring arrangement with knock out holes provides for easy disassembly |

|

| |

|

| |

Flow Seal |

| |

| |

|

• |

Fully Stellited, body & Disc seat |

• |

Seat rings - Seal welded to body |

• |

Lapped Seat & Disc faces for leak tightness |

• |

Streamlined flow path ensures minimum pressure drop |

|

| |

|

| |

Disc Design |

| |

| |

|

• |

Self aligning disc ensures perfect seating |

• |

Designed to open at low differential pressure |

|

| |

|

| |

Design Specifications |

| |

|

| |

General valve design |

ASME B 16.34 Special class |

Pressure, temperature rating |

|

Buttweld end design |

ASME B 16.25 |

| End to end dimension |

ASME B 16.10 |

| Testing |

API 598 |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|