|

Knife Gate is one of the few application - specific designs among industrial valves. It basically features a design that ensures minimum contact between moving parts of the valve. This is achieved by having a gate that is practically held between layers of gland packing without touching the body parts during most of its travel.

The seating itself is accomplished with a non- sliding motion aided by jams located in the body. Avoiding sliding contact between gate and body permits this valve to handle abrasive particles present in the media much better than conventional designs.

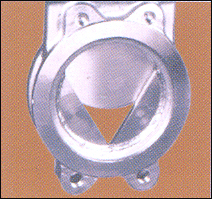

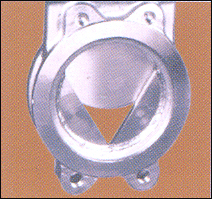

Another feature is the bevelled bottom edge of the gate (from which it derives the 'knife' in its name) which allows positive closure of the gate even when solid particles settles at the bottom of the body.

In handling abrasive media, deflection cones are generally used in order to avoid direct impingement of the media on the seat surfaces'; hard facing of seating parts is also sometimes used which involves stelliting of the seaaaat or gate or complete nitriding of body and gate.

Anothe feature is the purge connection which let in suitable fluids at pressures higher than line pressure to clean seating surfaces (body purges) and packing area (chest purges.) This minimises abrasive wear and tear during valve opening and closure.

Knife gate valves are excellent hopper isolation valves with their ability to cut through flowing powders and close by dislodging any material in the seating area. This is also perhaps the only valve design which can tolerate differential thermal expansion of its parts without affecting its functions, thus making an ideal choice for handling high temperature media.

Knife gate valves are generally uni-directional valves; however, modified designs are also available to handle bi directional shut - off requirements. offers a wide choice in designs and options in their knife gate valve range.

Type

|

Uni- directional Cast Body High Performance Knife Gate Valve. |

SIZE

50mm to 600mm for standard range; higher sizes upto 1200mm as specials |

| |

Design

|

Design with no welding on pressure holding body parts;

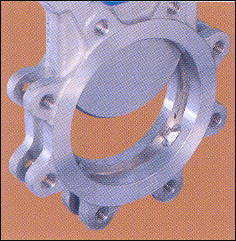

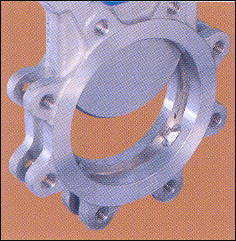

Lugged and Wafer, round port with metal - to - metal seating as standard.

Resilient seat

V-Orifice, Square and Rectangular port options also available.

|

| |

Testing

|

Body Hydrostatic

Testing : Conforms to MSS SP-81 upto 600 mm; proprietory norms for higher sizes.

Seat Leakage Testing:

Conforms to MSS SP - 81 exvept for valves with nitrided body;

Conforms to Proprietory standards with nitrided body; bubble - tight with all resilient seat options.

|

| |

Materials

BODY

Stainless steel (CF8 /CF8M) and

Cast Iron (IS 210 FG 220) as standard.

Cast Steel, SS 317 / 316 / 317L / 310 and others also available as specials.

Gate :

Stainless steel (304 /316) as standard; other grades available as specials.

|

| |

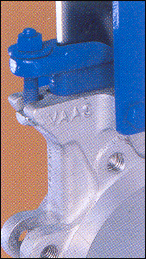

Packing

|

Multi -layer square section packing with externally adjustable gland. Braided yarn packing as standard;

non - asbestos packing available for temperatures upto 1200 deg. C.

|

| |

Rating

Maximum CWP of 10 bar upto 600mm for valves with body in stainless steel and special alloys, Max CWP of 10 bar upto 300mm and 5 bar upto 600 mm with body in cast iron/ ductile iron. |

| |

Standards

|

Proprietory design conforming to the following standards :

Design :

Face - to - face dimensions and valve port ID conform to MSS SP -81.

Working Pressure Ratings :

Proprietory - 10 bar upto 300 mm and 2 - 5 bar on higher sizes as standard. Higher ratings available as special designs.

Materials of construction for stainless steel valves conforms to MSS SP - 81. Body Construction conforms to MSS SP-81 for welding requirements. End connectionsuitable for mounting between companion flanges conforming to various standards such as ANSI B16.5 DIN PN 10, 16; BS 10, AS 2129 Table D and E.

|

| |

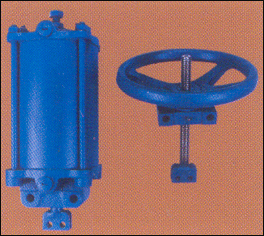

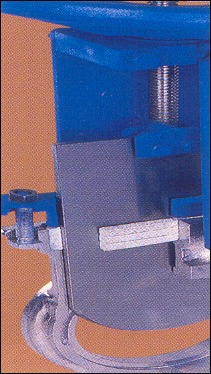

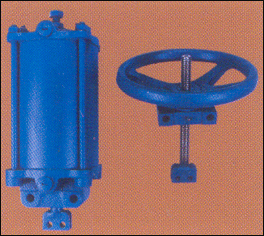

Actuator

|

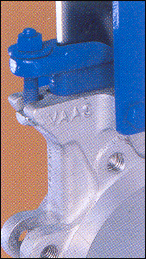

Direct mounted handwheel / chainwheel;

bevel - gear handwheel / chainwheel;

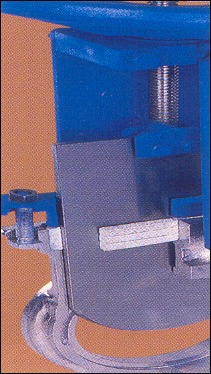

pneumatic double acting cylinder actuators.

Special - Features:

1. Valve design allows field interchangeablity between manual and pneumatic actuators.

2. Non - corroding, light - weight fibre - reinforced plastic (FRP) cylinder tube as standard. |

| |

Options

|

Deflection cones for abrasive flow application ; body and chest purges for slurry / powder handling. Hardfacing of seating areas (stelliting / nitriding) of seat / gate for tough services. Manual override for pneumatic actuators. Fail Safe System for specified air failure position of valve. |

| |

Applications |

|

Knife Gate Valves are used in a variety of applications such as:

Slurry Lines

Thermal Power Plants, Mining Collieries. Sludge and viscous media handling Sewage & Waste Water Treatment, Chemical Sludges, Sticky Media, Molasses. Pulp and Paper Stock Lines On - Off & Control Applications

Dry Solid and Powder Handling

Hopper isolation valves, Pneumatic conveying systems, Polymer chips handling Weighing & batching systems, Dryers; Coal burner valves to NFPA - 8503 specifications.

High Temperature Gas Lines

Carbon Black Plants.

|

| |

|

| |

| Typical media |

Typical media |

Typical media |

| |

|

|

| Dry Solids |

ESP hopper isolation Hopper isolation |

Thermal Power Various |

| Sludges |

Pumping stations |

Water & Waste water |

| Paper & Pulp stock |

On-off and control applications |

Paper |

| Slurries |

Wet slurry handling |

Thermal Power isolation Mining |

| Viscous media |

Molasses |

Sugar |

| High temperature |

Boiler bed ash removal |

Thermal Power |

| |

High temperature gases |

Carbon Black |

| Highly erosive |

Pulverized coal firing |

Thermal Power |

|

| |

|