2

T: 936-588-8350 • F: 936-588-8381 • www.craneenergy.com

Duo-ChekValves

Specify theDuo-Chek ...to your advantage

'

T

T

'

'

'

4QSJOHXJUI

WBMWFXJEF

PQFO

6OTUSFTTFE

TQSJOH

1MBUF JO

PQFO

QPTJUJPO

4QSJOHXJUI

WBMWF DMPTFE

1MBUF JO

DMPTFE QPTJUJPO

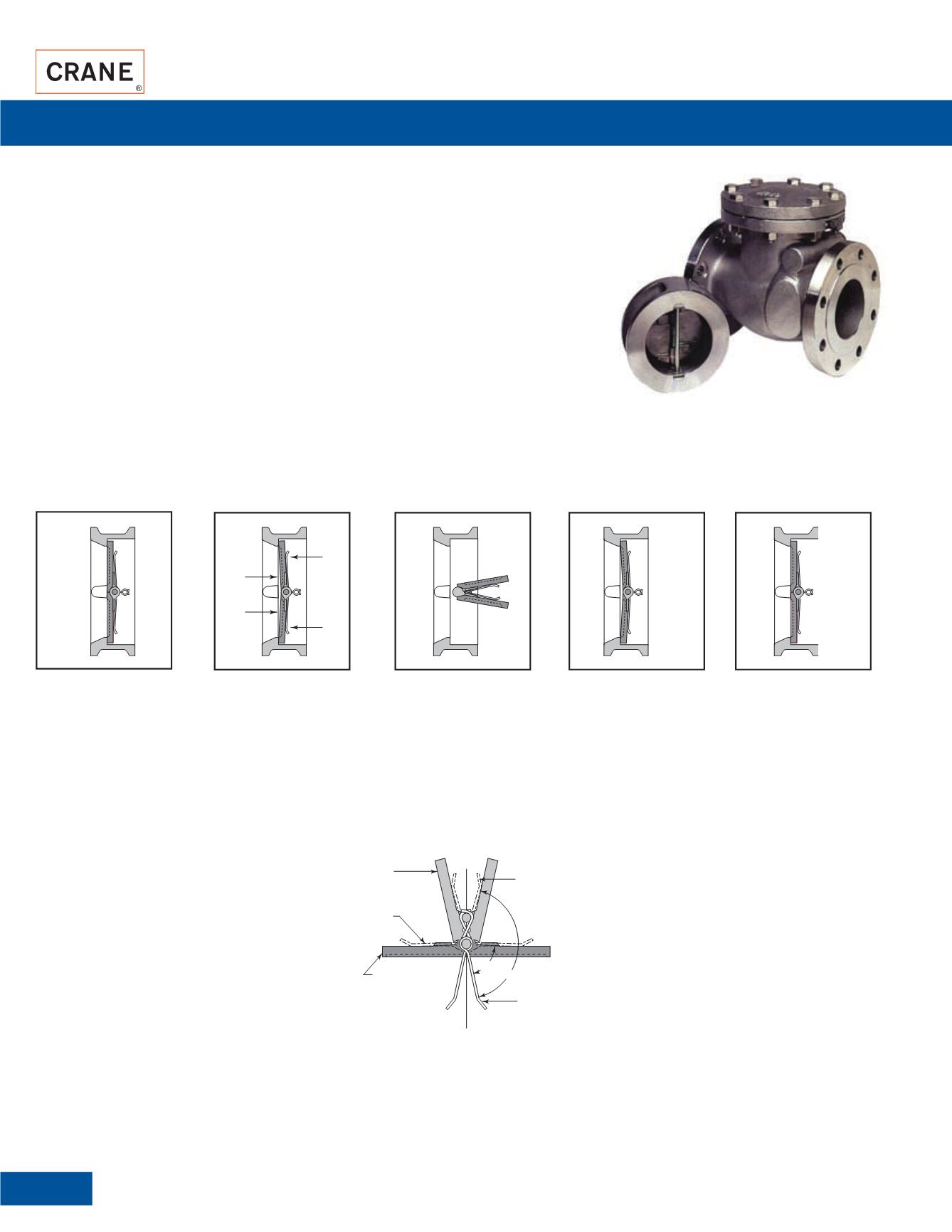

The innovative dual-plate design of

the Duo-Chek employs two spring-

loaded plates (disc halves) suspended

on a central vertical hinge pin. As flow

begins, the plates open in response to

a resultant force (F) which acts as the

center of the sealed surface area. The

contact point of the reactingspring leg’s

force (Fs) actsbeyond the center of the

plate area, causing the heel to open

first. This prevents rubbing of the seal

surface prior to normal plate opening,

eliminatingwear.

As thevelocityofflowdecreases, torsion

spring action reacts automatically. This

moves the plates closer to the body

seats, reducing the distance and time

of travel for closure. By having the

plates closer to the body seats at the

timeof flow reversal, the valvedynamic

response is greatly accelerated. This

dramatically reduces thewater hammer

effect for non-slam performance.

Plates in closed

position.Top view.

Heel opens first as

flow begins.

Plates fully opened (85°)

Plate toe closes first as

flow decreases.

Plates fully seated for

bubble-tight shutoff.

At closing, the point of spring force

causes the toeof theplates toclosefirst.

This prevents dragging of the heels of

the plates and maintains seal integrity

formuch longer periods.

Independent SpringDesign

A springdesignof theDuo-Chek (sizes

6" and larger) allows higher torque

to be exerted against each plate with

independent closing in response to the

processstream.Testinghasproved this

actionprovidesup to25% improvement

in valve life and 50% reduction inwater

hammer.

Eachof thedualplateshas itsownspring

or springs, which provide independent

closing action. These independent

springsundergo lessangulardeflection,

only 140° as compared to 350° for

conventional springswith two legs.

Independent

PlateSuspensionDesign

The Duo-Chek unique hinge design

reduces friction forces by 66%, which

improves valve response significantly.

Support sleeves are inserted through

the outboard hinges so that the upper

hinge is independentlysupportedby the

lowersleeveduringvalveoperation.This

allows both plates to close at the same

time for quick response, and excellent

dynamic performance.

Leadingengineeringspecifiersspecify theDuo-Chek forcheckvalveapplicationsbecause itprovides

high performance.Extensive research and testingwith demonstrated performance has earned

worldwide recognition, unmatched in the industry.

TheDuo-Chekwafer valvedesign is generally stronger, lighter, smaller,moreefficient

and less expensive than conventional swing check valves. Its designmeetsAPI 594

which is approximately one fourth the face to face dimension and 15% to 20% the

weight,onmostpopularsizes,making them lessexpensive thanaswingcheckvalve.

It ismuch easier to install between standard gaskets and line flanges.The savings

compoundduring installationdue toeaseof handlingandonlyoneset of flangestuds

is required.Therefore, it ismore cost effective to install, and also tomaintain.

The Duo-Chek also offers special design features that make it a high performance non-slam check valve.These include a

scrub-freeopening, and inmost sizes aunique independent springdesignaswell as an independent plate support system.

These featuresmaynot be found inother check valves.Other configurationsoffered include lug, double flangeandextended

body.